-

Posts

226 -

Joined

Everything posted by 4to5to6

-

Dating A Lachenal From The Serial Number

4to5to6 replied to johnconstable's topic in Concertina History

Please see attached photos… Is this 15769 or perhaps 55769? It is an early Lachenal treble that was modified with carved bone ends. It would be nice to know the serial and date. There are no other serial numbers except these two in the reed pans. -

Dating A Lachenal From The Serial Number

4to5to6 replied to johnconstable's topic in Concertina History

Thank you Wes! . -

Dating A Lachenal From The Serial Number

4to5to6 replied to johnconstable's topic in Concertina History

Can you please give me the approx date for Lachenal 184566, 20 button Anglo? It’s in very nice condition with the original leather baffles still installed (therefore makers badge and serial). In spite of all my efforts, two end bolts broke on disassembly but I can easily replace these. I really don’t think this concertina has been taken apart in 100 years!!! -

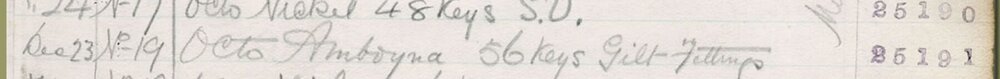

Yes. The ledger photo in the first post says “gilt fittings”. They are gold plated brass.

-

Wow! Someone did take a risk. Let’s hope it turns out to be a fine instrument. I can’t find the list now, but I went through all the ledgers before purchasing my 31xxx golden era amboyna model 19 TT and there were less than 40 made as I recall. The instrument cost me an arm and a leg but I do believe along with others that it could be one of the finest vintage concertinas in existence. It was well taken care of for its entire life based on its very clean condition and then meticulously restored and tweaked by a few of the best of the best including Steve Dickinson. I also have an exceptional 1856 Regondi / Blagrove era treble previously owned by the Bulteel family (Lord Revelstoke) and an Aeola treble built in 1942 during WWII (factory A440 with a factory 8-fold bellows) that is an exceptionally fine instrument with amazing reeds but they too are in absolutely pristine clean condition almost as new. They started out as top tier instruments and were always taken care over. .

-

How many concertinas have you owned/tried?

4to5to6 replied to LR71's topic in General Concertina Discussion

Probably owned between 20 and 30 over the years and have tried another 20 maybe in search for the perfect tone. I now would like to only play my prefered 31xxx amboyna Aeola TT to really know the feel of it well but I am often repairing or restoring an instrument that needs to be “played in and will switch to playing it full time until done. Best to stick to just one instrument and specialize in it. It’s okay to have a backup of course… I do have a Regondi era EC owned by the Bulteel family that is absolutely amazing at quite parlour music and a model 22 EC with short stroke buttons for fast playing that will peel the wall paper off the wall it is so loud so I understand the interest in multiple instruments…. I think it’s called G.A.S. (Gear Accusation Syndrome). . -

The Saleroom, Lot 338 https://www.the-saleroom.com/en-gb/auction-catalogues/burstow-and-hewett/catalogue-id-srburs10468/lot-b3ef5a74-e0fd-48fd-9c9e-b14900b82bc8?utm_source=auction-alert&utm_medium=email&utm_campaign=auction-alert&utm_content=lot-view-link&queryId=d1b7df1b61eae4d40d6fbe74e9b2418e C. WHEATSTONE & CO - a Victorian concertina manufactured by The Wheatstone & Co of London, serial no. 25191, pierced walnut casing, in original hardshell box, label inside reads C Wheatstone & Co It needs work. A diamond in the rough

-

Wow!

-

I have a 72 button McCann Aeola that I haven't used in many years. I've been keeping it as it is on the same ledger page as my Tenor Treble English. I can part with it if your son needs it. Metal ends replated, good bellows and tuned to A440, goes down to a low F# and built in 1919 as I recall. Where are you located? PM me your email address and I'll pull it out and send you a few photos.

-

Hi Derek, Where are you located?

-

Ok. Fair enough… I thought that the underlying discussion was really about musical expression in general. It’s really not my nature to be so blunt…. My apologies… This is a sensitive topic. It is a comparison between two entire types of concertinas and two entire groups of players. How do you answer a critical question on why someone does NOT do something. It’s like asking “Why doesn’t Jonny make his bed?” These are loaded questions. And besides, I did give a number of examples like Danny and Simon that use bellows changes extensively as well as some pieces I play that extensively use bellows changes. I practice scales using bellows changes on every note. The fact is that a very disciplined and well studied English concertina musician will use a lot of bellows changes as expression and everything else they can at their disposal. Why wouldn’t they? Music is expression as I explained in great detail previously. You only have the bellows and buttons. The short coming of the concertina, in general as an instrument, is the lack of balance when you play two notes (specifically treble and bass notes) that are far apart. I do believe the advantages outweigh this disadvantage or I would play the concertina. The beauty of the English Concertina is that you don’t have to make the bellows changes if you don’t want to. Like Leah said, “I’d be excited to change bellows whenever I wanted”. However, if you are lazy, you can choose not to on the EC. Unlike with an Anglo Concertina where you must make these changes. I’ve yet to see an Anglo player do cross row fingering legato. The beauty of the EC is that you have the choice as Leah stated. What if I started a post asking “Why don’t Anglo Concertina musicians play legato or smoother? Would not the answer be the same? Or (fighting words) is it not possible? People can be lazy. It’s harder to use the bellows on the EC to make “bombastic percussive expressive” passages just as it is hard to play legato passages on the Anglo. .

-

Check out Simon: or his awesome Roll technique Let me ramble on a bit and try to approach this from a different angle… How about defining “expression”? Expression in music is a huge topic… I remember years ago making a list of all the different characteristics of music I could think of and the list just kept growing to over 50.., One short list was: articulation technique feel dynamics rhythm tone phrasing space listening All of these are “expression” and the bellows have a big part. Different colors and brush strokes as an artist would say while painting. This said, every instrument and “genre” has its own characteristics… I think what we are actually talking about in this discussion when we say bellows “expression” is more traditionally called “percussive articulation”. The Anglo Concertina is growing in popularity along with the growing interest in TIM (Traditional Irish Music), which is amazing! Most would agree that the Anglo is better suited to TIM than the English not to say that you can’t be very, very good at playing TIM on the English as many musicians past and present (Simon) have proven… It’s just a bit more natural on the Anglo (rolls, cuts, etc. and being diatonic by nature). What is TIM? Another big question! I played the Irish whistle for many years before switching to mainly the EC about 10 years ago. With the diatonic whistle, I used to spend a lot of time practicing articulations such strikes, cuts, rolls, crans, etc. which I came to realize one day were the defining sounds of the uilleann pipes and so concluded that really it was the unique strengths and limitations of the pipes that actually defined TIM. I hope this makes sense. I’m not sure the debate about which instrument is best or worse at certain techniques is actually that healthy or productive on most levels. Learn to have fun and be expressive on what ever instrument you choose. That’s the fun of it all. There’s 80 year old Latin bongo player’s that have played their whole life still perfecting their technique. I was a rock bassist for many years, 4-string, then 5, then 6-string, now I play mainly the treble, TT and BT concertina… quite the switch. I love it. I am pouring everything I have learned for decades as a musician into the instrument. It’s a perfect match. I recently spent a small fortune on a golden era amboyna TT Aeola and am restoring a super rare 56B BT model 14. I even hope to build concertinas in my retirement and restore scrapped instruments to playable condition to pass on to interested young players. Here’s some “expressive” pieces… I love playing old Victorian music on the EC like say like Mr. Beveridge’s Maggot But also love tunes such as the Beeswing Hornpipe Or modern arrangements such as: I love playing fast but slow and smooth with expression is much harder. Or, for a challenge: I still haven’t figured out the middle eastern maybe Turkish? sounding section starting at 2:42 but I’ll get there. Have fun and play, play, play. .

-

Define “Expressive”! First thing,,, English concertinas DO have wrist straps! My 48B treble model 22 came with them as well as my Tenor Trebles and baritone treble. The Model 22 is a short stroke, small chambered EC that is made to be played fast and is over the edge loud by design as mentioned in one of the Wheatstone price lists. Second… I never considered bellows technique to be the defining difference between Anglo and English concertinas but whether you play mainly diatonic or chromatic music. I personally think the OP’s question is a logical fallacy called “begging the question”. I assert that there is no reason to not have maximum bellows expression with the EC. The bellows of an Anglo is bit stiffer than an English to prevent bellows bounce but otherwise there is no difference with bellows technique. This is like asking the question: Why can’t an Anglo Concertina play a chromatic scale as fast as an English Concertina? The EC must therefore be a much faster instrument. This would certainly ruffle a few feathers and may not be true depending on an Anglo player’s skill level and what/how they have practiced. Every type of instrument has there strengths and weaknesses but most can be overcome if physically possible with disciplined practice. All types of bellows techniques are learned. I will say that Anglo players are forced to learn superior stacato bellows control in this way early on and English players can get a bit lazy and slur all the notes…. Hey, on that thought… What about the opposite question??? Why can’t Anglo Concertina players be as smooth and legato as English Concertina players? Is this not also a big part of “expressive” bellows technique. Both Anglo and English have equal bellows expression but different challenges to overcome. practice, practice, practice… play, play, play… .

-

Good one Geoff! I’ll try this. I’m a big fan of one finger per column for single note playing. 4 fingers, 4 columns…. You loose the pinky support but it makes the instrument much more intuitive. I think this was a Richard Blagrove method from the mid 1800s. With multiple note, harmony playing, it’s all over the place. Opposite to the original question of moving one finger to multiple buttons… here’s Simon Thoumire moving multiple fingers to one button… he has an awesome two finger roll technique: .

-

Awesome! I’ll be the first in line!!! Thanks. Ok, 2nd in line…. Morgana is 1st

-

Hi Alex, Is this it: https://www.conservationresources.com/shop/archival-storage-supplies/hi-tack-fish-glue/ Very interesting. A cold-set fish glue!

-

Hi Steve, I don’t think you will beat modern PVA glue. It gets tacky at just the right time, glues leather perfectly, remains flexible and the excess is easy to clean off. If you want to bump it up a notch, use a PVA white glue that is pH neutral. .

-

The musical teapot is hilarious but I like the musical brush shown in the article even better. A stealth instrument! I could see using parts from a duet concertina and then blowing through the spout to make the reeds sound. The predecessor of the concertina was the symphonium, a reed instrument blown by the mouth. https://www.metmuseum.org/art/collection/search/502652

-

What our concertinas look like?

4to5to6 replied to new english's topic in General Concertina Discussion

Original pads, new valves, tuned to A440 and voiced. I’ve come to realize that it’s mainly about the quality of the reeds and how the concertina has been stored (cared for) over its life. This one started out as a “best of the best” 12 guinea Wheatstone. Emily Bulteel was a student of Richard Blagrove. Even the almost 170 year old case is nearly mint. Most of these hex cases have fallen apart by now. I brought the bellows back to full life with some Connolly Hide Care. I don’t know who tuned it to A440 but the steel reed profiles look great. It has the original leather bellows so a bit of a subdued sound and super expressive and responsive with amazing dynamics. It is my favourite at home, in the evening, concertina 2nd only to my golden era 31xxx amboyna TT that cost me over 20 times as much! I’ll get a few photo of it on here soon. Another interesting feature is that it only has a 5-fold bellows but the folds are very deep so it opens up a lot more than expected; I never run out of air. . -

What our concertinas look like?

4to5to6 replied to new english's topic in General Concertina Discussion

I’ll add a photo here later but I picked up one of these 12 guinea models in near mint condition with a mint condition case for next to nothing. It has become one of my absolute favourite concertinas: quite but super responsive with a large dynamic range . 7573 serial from 1856 is sandwiched between Regondi and Blagrove. I feel very privileged to be its custodian. -

Almost all of the old original tutors are available in the British Library archives. I understand that at one time, a copy of each book published was required to be sent to the British Library. Many of these have already been scanned or can get scanned on request. This also applied to published music scores. There is a fee for this service but found them very good to get along with. https://explore.bl.uk/ I’m a big fan of Richard Blagrove and found his 1864 tutor at the British Library along with a few other rare ones. https://explore.bl.uk/primo_library/libweb/action/display.do?tabs=moreTab&ct=display&fn=search&doc=BLL01004221696&indx=17&recIds=BLL01004221696&recIdxs=6&elementId=6&renderMode=poppedOut&displayMode=full&frbrVersion=&frbg=&dscnt=0&scp.scps=scope%3A(BLCONTENT)&tb=t&mode=Basic&vid=BLVU1&vl(297891280UI0)=any&srt=rank&tab=local_tab&dum=true&vl(freeText0)=Richard Blagrove concertina&dstmp=1697438988004 .

-

I’m an English player but did start out on a Crane Duet. I’m curious… what is the size (across the flats)? Gorgeous engraving!

-

Still searching. Thank you to those who have been kind enough to reply.

- 4 replies

-

- tenor treble

- tenor-treble

- (and 9 more)

-

BV - Bowing valve DV - Double valve SV - Single Valve (Slide Valve) KV - Key Valve it’s interesting to note that the fretwork of most SV concertinas also has the small SV cutout on the opposite side (both sides) wether it is used or not. Has anyone ever been able to “bow” their concertina? I’ve read the patent but it seems more of a marketing gimmick than something usable. I tend to prefer KV on the English but SV has never been a deal breaker. .