David Hornett

Members-

Posts

234 -

Joined

-

Last visited

About David Hornett

- Birthday 10/15/1950

Profile Information

-

Gender

Male

-

Interests

Varied music genre, playing and listening.

-

Location

Hobart

Recent Profile Visitors

3,035 profile views

David Hornett's Achievements

Chatty concertinist (4/6)

-

Dana, Thank you for extending your wisdom and encouragement those not so many years ago when I began making my concertinas; yes the the reeds are the heart of the concertina, and, as I discovered, the heart of the fun is making them. I read your posts with the alacrity and wonder of a beginner, and then as I progressed in another wonder at your depth of knowledge and willingness to share it all. Thank you so very much! David

-

Advice for thickness of leather for bellows

David Hornett replied to Rod Pearce's topic in Instrument Construction & Repair

I use kangaroo chrome tanned leather, skive to .5mm for the cover leathers, and use .3mm kangaroo gloving leather for the gussets. David Morgan on his website details the physical properties of roo skin https://www.davidmorgan.com/shop-content/comparekangaroo/ Elsewhere I have read even more robust figures. The skin, either chrome tanned or veg tanned skives very well, and in fact the .3mm gloving leather also makes for good bellows strapping. It comes in many colours. Packer Leather is a certified supplier: https://packerdirect.com.au/collections/kangaroo-leather (I recognise there is a repugnance for some against hunting roos, but, I personally have witnessed the absolute devastation roos cause to farmed and natural country, including National Parks, if left unchecked. Their numbers have increased astronomically since European settlement because of a now plentiful water supply, bores and dams, and cropping land. Further, in their natural setting their natural predators have been wiped out and in the bush their only control is now starvation and drought, or with exploding numbers to invade the farm next door and be hunted for meat and leather. David -

Reed slot stepped profile

David Hornett replied to 4to5to6's topic in Instrument Construction & Repair

Sorry, forgot to put the "." in front of the figures. The Indian stringed Tanpurra has a rounded nut, this helps generate its characteristic sound. As the string vibrates it is lengthened and shortened by where it grazes the nut in its vibration. (This is added to by placing a thin thread between the string and the nut so producing a buzz, made by the string's touching of the nut. The point of contact changes as the note dies.) With this in mind, a displacement of a reed's saddle in relation to the shoe could, maybe, change the sound, by producing a distinctive reed quality arising from any, otherwise imperceptible, buzz when the reed hits the overhang, shoe or saddle, in its swing; and also from the lengthening and shortening the reed in its swing .... maybe?? -

Reed slot stepped profile

David Hornett replied to 4to5to6's topic in Instrument Construction & Repair

Hi Chris, I also measured the few Jeffries reeds I have (Jeffries Bros, Praed St) for their alignment of saddle and shoe (reed pitch stamped as below): B#3 shoe alignment in front of saddle 22mm A# 4 3 mm G#5 2 mm David -

Detecting bellows leaks?

David Hornett replied to fred v's topic in Instrument Construction & Repair

I really think you have nailed it Chris, but before giving the instrument a bath you can use one of two methods , either Alex's above with a slight modification, lick your lips to make them moist pass them over the bellows, without touching the bellows of course, the leak will be felt on the lips as a soft cooling zephyr. You can also use a candle close to the bellows, but not too close, by its wavering it will pinpoint the leak. I have uses both methods with success, as well as shining a light inside in a dark room, but being the romantic I am the wet lips test normally suffices. -

If one can hold their breath and control the heartbeat it helps. A pencil's taper, ie the writing point where it comes out of the sharpener, also helps. Press the taper into the bushings on the endplate to give them a taper, and compact any small pieces of felt that may have dislodged. (I now use a tapered brass rod spun up on the lathe) Then stand the buttons all up straight, pray to which ever is your preferred deity and slip the end plate on. Working at a high bench helps greatly because if / when trouble appears one can peek beneath the endplate without lifting it up and displacing any of the buttons you have managed to centre in their holes.

-

Resources for concertina building

David Hornett replied to Fraxinus's topic in Instrument Construction & Repair

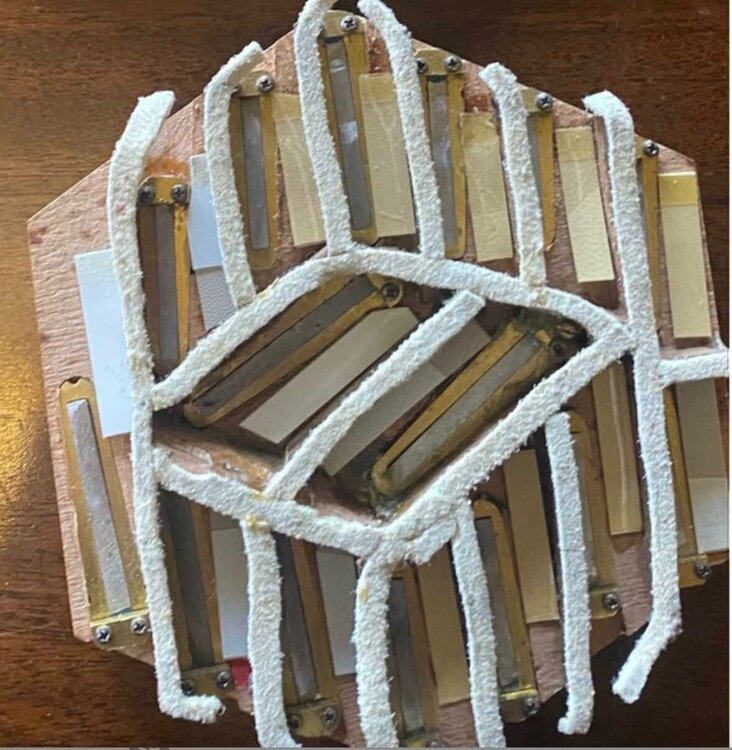

I have made quite a few concertinas, 37 to be precise, in 4 different sizes and different number of buttons: metal and wooden ends, from many different Tasmanian woods. It can become very addictive. I began knowing nothing, and the first four 39 button concertinas were basically unplayable because I guessed about profiling and was not aware of the critical aspect of precise fitting of the reeds, although I was at the time rather proud of the results of my efforts. It took me over 1000 hours to make my first concertina, the hardest part was making all the jigs: a little guided vertical router for the reed pans, the bellows jig, a sanding drum / thicknesser, button dies, a saddle screw jig, reed profiling jig and a button making jig, among others. Each 'tina takes about 120 hours now, but I am retired so do it in dribs and drabs between other activities. My last 4 took a month each. And as I have run out of shoe blanks, I suspect number 37 is my last. I designed my reeds to be parallel and wider than standard concertina reeds, (figured wider ones would be louder) thinking that tapered reeds would be harder to hand shape. They are not. Once I had designed the reeds (width and length), I got the shoes lazer cut commercially: 3000 of them in 14 different sizes from 2mm brass. I had considered casting them myself in maybe: bronze / brass / alloy, but figured that was going too far, so got them lazer cut. Each shoe still has to be undercut, have the saddles fitted and a 7 degree taper filed on the sides. My first reeds were made of clock springs, they worked, but after one instrument I settled with cutting them from plate spring steel. That worked better (no curve to straighten.) Each reed is hand cut and profiled: approx 4 reeds an hour, 64 in a little over 2 days if I get carried away. I have absolutely enjoyed the challenge; have given quite a few of my later 'tinas away: I treat it as a hobby, not a business, and have sold a few to cover costs. Each family member also has one to remember granddad/uncle by. At number 6 I decided to make no more; did the same at 10, then 20, then 30, and now am up to 37. Each time I decided to stop, I thought I might just try a small alteration, or reduce size to a smaller model, or try out snake skin rather than roo leather. It is addictive. My advice is if you would like to make one tina, or 37, do so. But you most certainly won't save money, unless you can get your hands on a good set of used concertina reeds for a pittance: but then there goes the challenge. The cost of all the materials, and the lazer cut reed shoes comes to approx A$600 each 'tina. And then there is the tooling and the jigs. Hope this helps: I have had a lot of fun, and have some very nice looking instruments that I enjoy playing; friends I have given them to tell me they also enjoy them. I hope they are telling the truth. David -

I have not used it at all. It was just amazement that such a thing could be done that made me pin the post, along with the thought that maybe someone out there may like to capture the sound of their favourite instrument in a form that could be used as a sound file in Logic Pro. Saxon is looking to use it in his compositions (his day job is a professional composer: adds, theatre music, music for singer song-writers, films and so on). He has sat down and played it to me, a number of different tunes and genre, on the keyboard, sounds great, but I can't play a keyboard so it is beyond me to have any use. If you look at his website https://saxon-hornett.com/ you will hear the type of material he produces, the stuff he has kept ownership of so can put on the site. Unfortunately he has not put the concertina up yet. He was hoping to sell it as a sound file, but I reckon the market for such a thing would be pretty restricted. If you are interested how he did it and how he intends to use it he is contactable through his site.

- 7 replies

-

- vst sample library production

- daw

-

(and 2 more)

Tagged with:

-

Yes. With mine he did four voices (sound files). 1, the 'as is'. (Precise samples of all notes as they are, worts and all) 2, the 'balanced voice' (balanced voice, volume and response) 3, The complete scale (stretched from G2 - D7 with all notes on the scale, including those not found on an anglo) 4, Complete scale, balanced, including breather hiss. He did it because, of the sound files he found, he found none that sounded convincingly like an anglo concertina when put into his compositions. (4 above sounds pretty amazing when a tune is played). I must admit I had not thought to direct him to concertina net, which I shall do now, Thank you David. But never-the-less, if anyone has the desire to capture the exact sound of their favourite concertina in a sound font, it can be done, which I must admit, until yesterday I had absolutely no idea was possible. (Please excuse my ignorance.)

- 7 replies

-

- vst sample library production

- daw

-

(and 2 more)

Tagged with:

-

Hi all, My son, Saxon, has just demonstrated how he can capture and digitally sample musical instrument sounds into a 'VST Instrument' using one of my Tassey Tiger concertinas as a sampler. This means the concertinas sound can be added to a keyboard through a DAW (Digital Audio Interface) and then played through the keyboard using all keyboard effects. I was amazed at the absolutely perfect replication of the instrument's voice. In short, the sound file can be added to the sound library of your keyboard. He asked me to write that if anyone is interested, and would like the sound of their favourite concertina replicated as a VST Instrument, he can be contacted through his website: https://saxon-hornett.com All the very best David Hornett

- 7 replies

-

- vst sample library production

- daw

-

(and 2 more)

Tagged with:

-

Chris, I will be at your lecture in a few weeks, and will bring my 30 button C/G parallel reeded Jones, solid wooden ends. It is loud, heavy, 17 cm across the flats, has bushed 7mm bone buttons and riveted action. It does not sound as sweet as a Lachenal, which I have put down to the parallel reeds, rather than Lachenal's tapered reeds: but I think there is room for debate here. I would not say it is much better than a Lachenal. I will also be at Numeralla. All the best David Hornett. David

-

A line concertina, been wanting to do this for years. BUT: Not as easy to make as I thought. Some of the Bass reeds had to be tuned 75 cents sharp of A 440 to be A 440 when assembled in the cover, (they were spot on when the comb with reeds inserted was out of the instrument's cover.) All I can put it down to is a tunnelling effect when blowing the instrument. I checked this theory out by reducing the mouth piece height, and thereby the venting holes' length, by 5 mm, this had the effect of reducing the bass reeds required sharpening about 25 - 30 cents depending on the reed (for instance, sharpening fell from 105 cents to 75 in some cases.) The middle reeds were effected by between 20 -30 cents, and the top reeds by about 15 - 30 cents. And talking about blowing, a very good set of lungs is required to supply the air through the reeds compared to a normal Hohner chromatic with their much smaller reeds. Reeds are stainless steel: my files will never be the same again! It sounds much more like a saxophone than a harmonica.

- 1 reply

-

- 6

-

-

There are up to 1 million kangaroos culled on the small island of Tasmania, pop.250,000 people each tear. (I have read this number, but cannot personally confirm it) One company. Lenah Meats in Tasmania prepares the meat of 60,000 of these each year for human consumption. Until recently all 60,000 pelts were thrown down the tip because there is a limited market, and overseas fashion industry, and international consumers began to refuse to purchase the skins. (Now they are trying to sell the pelts as ugg boots, which they call wugg boots because they are made of wallaby skins. There are a number of companies in Australia which now process Kangaroo skins, some of which still go into toys, aeroplane seat covers, high quality gloves, pipe organ leather, etc. But there are millions of skins that find their way to land fill / are left in the bush because of a restricted market. Millions of roos are killed across mainland Australia each year. Much of the roo meat goes into pet food. Farming communities have no alternative.

-

-

Yes I do agree, poor kangaroo. But, there is a bit of a bind, roos are extremely numerous, especially now that cattle and inland sheep stations have installed hundreds of thousands of tanks and dams for their animals, and this benefits roos too. Here in Tasmania we have mainly Bennetts Wallaby, a slightly small roo type animal, and because the apex predator, the thylacine, was wiped out in the 1930's all marsupial numbers have increased, often to plague proportions, in a boom and bust cycle. Starving roos are not a pretty sight, and and neither is roadkill, often caused by large populations of animals eating the greener grass on the verge. Last year my daughter did a research project on road kill in southern Tasmania. In a 6 week period on a 30 km length of low traffic country road (Geeveston to Dover looped through Police Point, have a look on google) we counted 183 fresh marsupial road kill that had remained on the road, many more, possibly double that number, would have crawled off to die. Absolutely awful. So I think it better to cull the animals, and put the carcass to good use. I also eat wallaby, it is a nice, low fat meat that is lovely in stew, I think it better than eating cattle and beef which causes enormous environmental destruction. And the skin is much stronger than bovine skin by a significant magnitude, waterproof and highly wear resistant and pliable, and totally sustainable.