Michael Marino

Members-

Posts

121 -

Joined

-

Last visited

About Michael Marino

- Birthday 06/26/1967

Contact Methods

-

Website URL

http://www.free-reed-foolery.com

-

ICQ

0

Profile Information

-

Gender

Male

-

Interests

Varied and many. Humanity was not meant to be insects.

-

Location

UK

Recent Profile Visitors

1,417 profile views

Michael Marino's Achievements

Chatty concertinist (4/6)

-

Is that a full leather box or is it a leather and veneer box? I have made leather and veneer boxes a long long time ago (I was teenager then). If it is only Leather that is going to be interesting as it is going to require a good bit of knowledge in leather craft. Best of luck and please keep us up to date if you do choose to make it.

-

No not Spam, a hot glue pot for folks who either work on or repair concertinas. Very useful in the making of traditional bellows. Made more than a few with this pot and repaired more than a few accordion bellows with it as well. just it is not functional in 110V system (which the US is). Hope that clarifies things even a good bit more.

-

Folks, Due to moving to the US my very much loved Hold-Heet is looking for a new home. I am in the Edinburgh area and if anyone is interested please reply here or PM me and will discuss price. It is in good condition and willing to have either in person or video inspection by those who maybe interested. Donation as normal will be made upon sale. Edit to clarify as was kindly pointed out is Hold-Heet Automatic Glue Pot Model 2301 240V 144W, Used and complete (this model did not come with a temp gauge. Cheers, Michael

-

Hello Folks, It has been years since I have been on the forum and life has been interesting (kids and many other items). I am getting back into my playing again as I am finding it helps deal with a good bit of stress. Though i am also in the process of moving the family back to the US (My lady wife is already there working). As such i will be asking folks if there are groups for playing and getting skills back in the South West Michigan area and trying to get the fingers back yp to the speed that they shoul be at. Anyway thanks for keeping this forum going and may your days bring you joy. I play Anglo currently and my wife plays English though she is looking at wanting to learn duet and I have been trying out a Bandonéon a bit as well (helps on muscle recovery a lot) Michael

-

For sale as stated in the header is a Stagi English Treble Concertina that my wife plays occasionally. it has been upgraded to having padded goatskin leather thumb straps as she disliked how the Stagi straps tended to cut at her thumbs during any serious amount of play. Bellows are sound and comes with the hard case. as all on this forum know this is a beginners instrument. Price is £400. Reason for sale is we are in the process of moving and reducing house items, she plays three other instruments more often then the Stagi so it gets to go. This link is to pictures of the instrument on my google drive: https://drive.google.com/open?id=1DdIeIgPKCrIYcjNxI4hoaXgCgUhIbcWf Normal donation if sold via the forum

-

No not imaging it. Well documented fact of metal stress and tuning/shaping of metals. The preceding post are very correct in that. Nothing I can add fro my own experience as they have pointed pretty much all of it out. Michael

-

My first question is wear are you feeling or noticing the stress or annoyance? From that point we can look at what would be the best fix for the issue. Michael

-

Alan, I am been extremely busy with life and family so have not even known that the last pages had ben finished. First thanks to all who helped with this. Second I will be down loading the pages tomorrow and having a look at them. The first section was most useful so I don't see why it should not continue to get better as a training tool as well. Take care and have a great day. Michael

-

Okay folks, Good points all around. I am biased as I have owned (sold due to needing more cutting area and better repeatability) and cutting building a CNC gantry router. Currently I cut parts for Chromatic harmonicas on them and able to get very high level finish and and repeatability. The new one will have a 4th axis (a spindle in line with the X axis) which will allow me to do a lot more 3D cutting which will allow even more precise cutting of combs and other items. Now let's look at expense, to build and use one of these has some very important costs that must be considered. They are the following with a rough range of prices (some of which you can get a very good product at a very reasonable price and some not): 1)CAD software for model creation £75 to £5000+ and add on to that the time needed to learn to use it well which normally can run over 30+ hours of use and study. 2)CAM software to generate the g-code for the machine to use (some 3D printers include their own version of this and you pay for it as well). Add another 30 hrs minimum in learning and study. Cost runs from about £90 for a good 2.5D CAM package to over £7500 for some of the truly professional stuff. 3)The machine(s) which depending on which route you go can run from around £1500 (home built and you have the tools or know some one who will help) to £5000 for a good base line built machine and the cost goes up from there. Oh yeah there is also the learning curve on the machine, which is an on going process. 4)A computer that has as it's only job the control of the machine (does not have to be fancy but 2Gig RAM is wise to have on board) 5)Control software which ranges from £90 to I don't want to know prices. I strongly suggest Mach3 for anyone thinking about this type of technology (3D printer have this built in and you pay for it in the price). 6)Then there is all the bits and bob's that include you end mills, clamps, material for jigs and such That is a never ending cycle of learning and keeping what works and getting rid of what does not. Back to concertina making. With the new machine I will be able to finally cut the face plates and do so with high repeatability (.05mm is what we are shooting for). But that is only part of it as also still need to build the bellows press and get better at skiving the leather for the bellows (though the wife is getting better then me and might just let her do it). While technology does much to make the making of things easier, there the price tag of taking the time to make the model or the machine to do it. Not a problem but must be taken into account. Now IF anyone is interested in building a gantry router or converting a mill or Lather to CNC, please let me know and will help any way that I can. My apologies for the long post but since I work with the technology to make parts already, I thought a good look at the costs might be in ordered and I know I have missed an item or two. Michael

-

Only a week to Button Boxes and Moothies

Michael Marino replied to Simon H's topic in General Concertina Discussion

I am planning on going, still need to finalize a few things but looks like a green light so far. I am in Edinburgh if anyone is heading by this way and willing to share space in a vehicle and the cost of fuel. Michael -

Alan thanks for your work and the of RAc as this is of interest and now that I have downloaded it will rotate the pages and start looking into it with interest as the wife has been playing a few of the tunes from the first download and the exercises will help both of us and the music will be wonderful to see how it comes along. Once we have things going better will give more feed back. Michael

-

Just a friendly bump to see how things are going with this. I know all to well how life can get truly busy and complicated with even trying, so as stated just a friendly bump to see and ask. Michael

-

Face plate design

Michael Marino replied to Michael Marino's topic in Instrument Construction & Repair

Again folks thanks for the input and will look into options. I own a small (240x210x45[-tool L], X,Y,Z) gantry router that I use for cutting small items on that I should be able to cut the fret work on. Right now don't have the safety equipment for cutting metal with it set up so that would need either that or out sourcing. Again thanks and will look into laminates other options. Michael -

Face plate design

Michael Marino replied to Michael Marino's topic in Instrument Construction & Repair

Dave, Currently looking at wood as don't have metal cutting of the type needed for piercing work. Looking at Maple currently. I have access to a wide range and if anyone has any suggestions please fire away. If anyone knows of a resource for doing it in metal I would also be willing to listen as I know that there are those who prefer metal ends. Thanks for the response and questions. Michael -

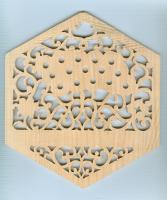

Folks, This is a test cutting of a pattern I am working on for making some concertinas. It has been a slow process as doing this between clients work. Progress is moving and would like comments on the design. Its is rough and needs a bit of cleaning, that I know; just looking for views on the design and balance. Thanks is given to Richard Morse (I miss his insight), Bob Tedrow (Thanks for your support Sir), and Dana Johnson for some insightful input and comments. Well back to the shop and more client work (Super 64X finish tuing and a Seydel Chromatic). Looking forward to responses. Michael