Sal79

Members-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Interests

Too many musical instruments, I play some too, mostly spueeze boxes.

-

Location

Up state NY

Recent Profile Visitors

469 profile views

Sal79's Achievements

Member (2/6)

-

I worked briefly with some piano technicians and came to the conclusion I don't have a great ear. All the reeds seem to be a full half step above my piano which I do know is flat, but not that flat. If I had an electronic tuner I might give it a go but I've had enough frustration and am going to give it a rest for now. My piano accordion needs a little work, think I'll fiddle with that for a while. Thanks, Sal

-

Sometimes you just can't win. Finally completed that little Italian job ie.the anglo with the backwards left hand and it's still weird (that's the most polite word I can use). It has a clear tone, almost like a violin. However the notes on the bottom two buttons in both keys make no sense, at least not to me. Specifically there is no lower B in the key of C which rules out some tunes and the key of G seems to have an A# at the bottom. No, I don't know how or why. I did learn some techniques and found a parts supplier, and it was an interesting project, but I'm back to my original question "WHY DID THEY MAKE THIS CONCERTINA THIS WAY? Sal

-

I made my new manifolds and attached them with "Amazing Household Goop" tm. It actually mimicked the original adhesive; which was not hide glue and took an hour and a half boiling and scraping to get off. Waxed in the reeds with my excellent cooker and paintbrush technique. Reinstalled the keys, made small adjustments, and viola: three dead reeds. I think I contaminated them with wax. I might try to clean them with lacquer thinner. How about the leathers? Thoughts? Sal

-

I'm back, behind schedule as usual. I would not recommend this project to anybody but now for me there is no turning back. The reeds came out easily however the "manifolds" are glued down with something impenetrable. I thought maybe I got a whiff of hide glue when I heated it up with my mini-torch. I can chisel them off but a solvent would be nice. Second: What glue might work to adhere the new manifolds? Years ago I helped a friend who did stringed instrument repairs. He swore by hide glue; I'll never forget the smell; no, I'm not conteplating a glue pot. Besides, that was wood to wood and meant to be easily reversible. Third: I toasted one of the leather flaps on one reed. (I know, don't do that!) I think I've got an old reed I can steal one off of but again, what glue? Forth: I've got beeswax but might use some additive or maybe get the proffessional product if convinced it's necessary. Below pictures are of my one candlepower wax cooker and a prototype manifold made of fine grained redwood. I was worried the fingers would break off but they seem sturdy.

-

I've looked at a few waxing methods on YouTube. I'm sure I can make something work. The geometry is going to be more challenging than you think. Though I am obviously not a free reed repairman what I see on the net and from experience is that the air from the valve enters at the riveted end of the reed. Therefore just turning the manifolds will screw up that dynamic. I expect I'll make new wooden mounting blocks and reset the whole thing. I do like a project. I'll be back in touch in a couple of weeks and let you know how it went. Sal

-

OK. I've been thinking this over and do believe with a little jiggering I might make it work. Whether I use the old wooden plates or make new I will need to reattach the individual reed blocks. I did wax in a few accordion reeds some years ago. It was ugly but it worked, very similar to my welding technique. Is there a better way? Seems like somebody must make something like a hot glue gun or even a product that would work in a hot glue gun, of which already have a couple. Sal

-

Thanks for your interest. I'll try to be clear. The buttons are on the outside and reeds on the inside of a single plate. It's the same plate flipped over in the two photos. The push pull relationship is standard. The problem is that there is not physical room to put the lowest, longest reed where the highest, shortest reed is now. It will hit the bellows frame. Perhaps you can see in the photo that the wooden mounting block is clipped on the outside corner to clear the inside of the bellows frame. What might not be clear is that the mounting block actually tapers and is narrower on that end. Even if I made a new block (no problem, I am a woodworker) it will not fit. Thanks again. Sal

-

OH EXPLATIVE ! I've been down this road before, like when I thought I could repair my Fiero's transmission, pulled it and found it needed to much peripheral work. Oops, wrong forum. In short, if I reverse the manifold blocks I'll also reverse my C and G rows. Furthermore if I try to reset the individual reeds there won't be enough room for the base reeds on the treble end, even if I make new manifolds. A new plate and linkages would do the trick but that gets into the realm of insanity, much like my late Fiero. I'm stymied. Sometimes the best thing is to know when to give up. So I'm back to the question, "Why did they make this concertina this way?" Sal

-

I've got it! Those folds of aluminum around the linkage plate were clips. They came off easy. Only a light pry to remove the plate. It all looks original inside. Is it possible I could reverse the reed plates and re wax them? Best method? Sal

-

Ps. There are some tiny holes filled with wax maybe 2mm. Could there be very tiny screws buried in there. Since the holes are partially covered around the perimeter I dismissed that notion. Sal

-

I am an inveterate tinkerer and I don't have so much invested that I wouldn't take a gamble. It is a nice sturdy box with better sound and smoother action than my old unit. Short of sawing the end off, does anyone have a suggestion. I hope you can see from the photos that two screws hold on the end cap. The are screwed into the wood between the white band (wood, not plastic) and the aluminum wrapped plywood that hold the button mechanism. Seems like what the end is screwed to must be permanently attached to the bellows. Therefore the break must be on the inside face of the aluminum. Any thoughts? Sal

-

20-Button Lachenal With Unusual Layout...

Sal79 replied to Roger Hare's topic in Instrument Construction & Repair

I am not a regular on this site but I just had a similar experience. My lefthand side is upsidedown or backwards if you will. Thought it was unheard of but now I hear from you. Maybe they were customs, or were they mistakes? Sal -

Thanks for your replies. Re: Don #1 I took the end cover off again. There are no fasteners left on that side. I tried prying if it was a friction fit. I tried a sharp edge tapped in if it were hide glue. Nothing. I am convinced I can only do damage at this point. I know the dealer pretty well, I expect he'll give me a credit. Re: Don#2 I live about ten miles south of Syracuse. Sal

-

On the anglo that I play the C row is: push/pull C/G G/B C/D E/F G/A I believe that is standard.The new box is: push/pull G/A E/F C/D G/B C/G Sal

-

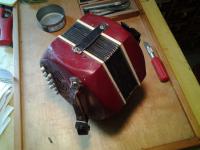

I recently bought a "new" concertina at an antique store to upgrade my existing box. I currently play an economy box from the 50-60's that is a little weazy and cranky. My needs are limited. I play folk songs, Christmas carols and Woodie Guthrie using the hand held harmonica with bass approach. The "new" box has aluminium ends with heavy maroon textured paint. It says "BREVETTATA MADE IN ITALY". It had no straps but I tested it in the store by holding one end between my knees. All the buttons work and the bellows are tight. It has a clean bright sound and seems in tune to my inexpert ears. Here's the problem. The left hand side is upside down ie. the low notes are on top. I thought it might be reversible but upon taking off the end plate there seems no way in and I didn't want to use force and risk breakage. I will mention I've had a few accordions apart and done some repairs. Everything was always self evident. Not so this time. So why was it made this way? Is this a weird variant or was it customized? Someone played it a lot. You can see by the wear on the finish. Thanks in advance for any insight you can give.

.thumb.jpeg.09943e9e2f2a23918324c6151aa2597b.jpeg)