-

Posts

246 -

Joined

-

Last visited

Posts posted by Andy Holder

-

-

I considered a Slingshot manouevre, but decided in the end that , given the year and the circumstances, the Javelin Concept was more appropriate, Hence, I make the move to Kensington (Olympia), leaving behind the greenery.

It might seem blindingly obvious but, Kentish Town.

Andrew

-

Hello all. I started lessons in Nov. and I love it. I bought a Wheatstone No.57639, which I think is just lovely and is the best thing ive ever bought!!! I spend hours practicing and have a few tunes. I have been reading all about different wheatstones and it seems that the Identity number of mine is "one of the not so good type" can anyone tell me anything about this. I didn't know there were all different qualities when I bought it. to me it sounds great.. especially when anyone elso plays it.... especially mymusic teacher.

I really enjoy all the information I find here from you all. Thanks.!!!

PS.. tis an Anglo 30 button.

Hi Sally (or Zoe)

If I'm not mistaken it was made on the 31st January 1956 (I was 5)!

You'll find the relevant page in the production ledger here

If you get joy from it then that's all that matters. It won't be long before it sounds gorgeous when you play it too. Good luck with it.

Andrew

-

I have posted some pictures on my blog http://edgleyconcertinas.blogspot.com of a very recently made concertina. It is rosewood, but has brown bellows. Please visit my blog and give me your opinion on them. Thanks.

Beautiful instrument Frank. If I'm absolutely honest, I'm not wild about the texture of the leather.

Andy.

-

I am very new to the concertina world. I have a 20 key G/D box and

while playing have one issue. While I am pushing or pulling- 3 of the

low note keys individually, I hear a faint hum or vibration while the

note is being sounded. Is this normal on the low notes?

thanks,

Bruce

Hi Bruce, it may be that there is a bit of contact between the reed and the reed frame, which would give a buzz. Or maybe some accumulation of dirt or rust on the edge of the reed or frame. If you have or can get the "Bible" by Dave Elliott it will tell you how to clean reeds.

Andy.

-

I have a different question about the leather valves. ( I just bought a copy of Dave Elliott's book on eBay, so I have about a week or two before I see it. Meanwhile. . . )

What kind of glue should one use to glue the leather valve to the metal read block?

Thanks

Hi Alex. The leather valve isn't glued to the metal reed frame. It's glued to the wood on the other side of the reed pan from the reed, over the slot cut in the wood. I use Feibing's Leathercraft Cement See here which I think is just PVA but twice the price. Still, it sounds good! Some people use a mix of PVA and cornstarch glue and the real masochists use animal hide glue!

On this concertina, it is glued to the metal reed block. This is a Scholer 20 button concertina that I am fixing up to have something that a real sailor would use. The one I am fixing up has a total of 12 trapezoidal reed blocks - each reed block has 5 reeds for the push, and 5 for the pull. There are 3 reeds per note, giving the pitch in 3 simultaneous octaves. It is a little late for me to photograph it right now, but I have a photo of another smaller Scholer that has only 1 reed per note, and therefore has only a total of 4 trapezoidal reed blocks. This one I am cannibalizing for parts. Here is 1 of its reed blocks, showing 2 of the leather valves glued to the metal reed block:

I have something called "Eco-Flo Tanner's Bond Leathercraft Cement", that is the same thing as Feibing's Leathercraft Cement. I would not be surprised if it holds the leather to wood, because wood is porous, but it is metal that I need to know about.

My apologies Alex. My lack of knowledge, I'd never come across that type of instrument before. I see your problem. Theo's idea sounds good. When you say a real sailor, are you planning to use it on a boat? On my boat, everything non ferrous rusts very very quickly! Especially dissimilar metals next to each other. Good luck.

Andy.

-

I have a different question about the leather valves. ( I just bought a copy of Dave Elliott's book on eBay, so I have about a week or two before I see it. Meanwhile. . . )

What kind of glue should one use to glue the leather valve to the metal read block?

Thanks

Hi Alex. The leather valve isn't glued to the metal reed frame. It's glued to the wood on the other side of the reed pan from the reed, over the slot cut in the wood. I use Feibing's Leathercraft Cement See here which I think is just PVA but twice the price. Still, it sounds good! Some people use a mix of PVA and cornstarch glue and the real masochists use animal hide glue!

-

The sad thing for me is that I feel I'm ready to take on a refurb of that sort, but I can't get a look in, don't have the spare cash! So I end up doing the lower end instruments, which are great, but not quite as challenging.

Andy,

From experience - some bitter but some pleasant as well - you may find that the lower end instruments are much more challenging to repair or restore than one of the "better" names. The quality of materials used in the lower end instruments can result in a real struggle to achieve a halfway decent end result.

It's probably also common that in your restoration, you've spent more time on the instrument than the original maker spent in its initial construction!

Alex West

That's certainly true Alex, although it's a very steep learning curve and you soon get to know the shortcuts.

Andy

-

You're right Alex. I checked too. I guess they must take a random 2 characters from the username and put 3 stars in between. It seems to stay the same each time though.

I didn't really expect to get it for 2.5 I tried for a couple of Jeffries' in auction houses down here. One went for 4,200 and the other for 3,100, plus 18% commission of course. I think Chris got those. He must have a very scary cash flow! (and good insurance!)

He undoubtedly knows his market very well, although his ECs on ebay haven't been selling recently, there's a lot of re-listing.

The sad thing for me is that I feel I'm ready to take on a refurb of that sort, but I can't get a look in, don't have the spare cash! So I end up doing the lower end instruments, which are great, but not quite as challenging.

Cheers. a***0

-

I don't understand. How do you know the winning bidder is Chris Algar? I know his user name on ebay but that isn't shown in the auction. Have you followed him so long that the number of winning bids in his history gives him away?

Ebay aren't that clever. Chris's name is cocoa11 so they use the second last character, star star star, then last character - 1***1

Mine would be 2***0 but I've never bothered to look.

Andy.

-

Yet another win by Chris Algar You have to admire the man http://www.ebay.co.uk/itm/Jeffries-31-button-Concertina-Restoration-/130628000433?pt=UK_MusicalInstr_Keyboard_RL&hash=item1e6a091ab1

I went up to two and a half, thought that would be enough

-

Hi Andy,

I think your idea is pretty good, and similar to another technique which I used after reading an earlier discussion on bolt hole damage. Dave Robertson had a tip about using modellers brass tubing which can be cut to size and glued in with Loctite. The thread is here:

I tried this out myself on a Lachenal that had woefully bad boltholes and it worked quite well. Can PM you some pictures if you're interested...

Michael.

Thanks Michael. I'd be interested to see the pictures.

Andy

-

I don’t know how to say this without pouring cold water on what, on the surface, looks like a very good idea so I’ll jump straight in.

Some years ago I had a concertina with a similar problem although not quite so severe and considered something similar but abandoned it for the following reason:

On my Maccann, which does not suffer this problem, the depth from the screw head to the bottom of the “pallet board”, ignoring the skirt that may offer some substance, is 10 mm. With the “ferrule” being 6mm this only allows 4mm for the “bite”. This may not be a problem but I wouldn’t want to risk it unless the “ferrule” was suitably keyed and glued to the surrounding wood.

Sorry, hope it doesn’t offend, just my take on it.

Hi Tony, No offence taken in the slightest. I'm always anxious that discussion eventually gets to the best outcome. I agree with you, that in many circumstances, 6 out of 10 isn't enough. Ideally you would seek a shorter insert and, as you say, glued and keyed. It was meant as a quick fix and in the case of this instrument, there is certainly plenty of good wood left and, because it is a tight interference fit in the hole, I feel gives adequate strength to the fixing. I did consider gluing in small dowels but I don't really like the idea of mixing end grain and cross grain, also dowels can shrink dramatically across the grain. Isopon or epoxy would do it but doesn't seem right in the spirit of the thing!

Thanks for the input.

Andy.

-

That is the typical description of a valve not lying flat so it closes when pressure is applied with the bellows. Even with new valves this can happen if for example the valve has a defect, eg a crease, so it fails to close, or it is catching on the side of the reed chamber. Sometimes the former can be cured by stroking the surface of the valve with the flat of a screwdriver blade which slightly stretches the top surface. If the latter then replace the valve positioning it clear of the chamber wall.

Thank you Theo. That's brilliant. I'll have a close look and probably replace those valves. I bought two beautiful hides of hair sheep yesterday which should keep me in valves for the next 10 years!

Cheers

Andy.

-

Sorry, I seem to be pestering with so many questions. I have a few notes where, if you play them very slowly and quietly, just after the reed sounds there is a sort of click and then a good sustained note, I'm guessing it may be the valve fully closing. All the valves are new and I've checked them. Will this just "play in" as the valves bed down? It only happens on a few.

Thanks.

Andy.

-

Thanks Frank, Geoff and Chris. I looked at them both under the microscope and couldn't see any witness marks of touching. No touching the wood either. Cleaned them both and put them back in. The noises have now gone away! Which is really annoying because I don't know what it was. Possibly not seated properly in the slot. Valves seemed fine, they're all new.

The only issue now is a slight clicking, presumably the valve. I'm going to post a separate question because not many people will look at this now.

Thanks again.

Andy.

-

Looking at the strap screws on an old Wheatstsone,where most of the Nickel plate has worn away, I notice that they have been made from two parts soldered, or Peened, together. When you make a lot of parts like this then the saving in material costs might be significant but my main thought was that in the 1800's Labour was perhaps cheaper than materials.

If you're machining from solid, the swarf is probably 80% of it, which, even if material is cheap, is a helluva waste!

-

I've got a strange reed, it's the A below middle C. It firstly has a metallic vibration and then it sort of growls! It's bang on the note but this growl is something I haven't come across before. It looks identical to it's twin (EC) the clearance looks fine, there's no crud hanging around and it's nice 'n shiny, nothing on the surface. I can't see any crack anywhere and it twangs the same as its mate. The valves are new and it's definitely not a beat frequency. Any ideas? It's driving me mad! Thanks.

Andy.

-

That was a great video. Thanks very much for sharing it. I wish there were more like that.

Thanks to Henrik for unearthing it. I've started work on a replica machine (with some more modern bits!)

Andy.

-

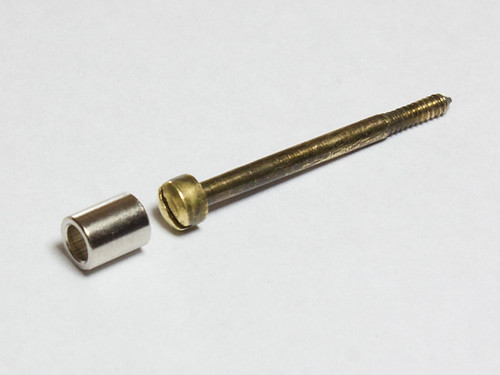

I thought I'd share this bit of good fortune, it is an accidental discovery which might save lots of work. I'm restoring a Maccann Duet which I bought off Chris Algar a while ago. The end bolts have been screwed down over the years so they are now sunk right into the wood. I was going to fill and re-drill the holes but I remembered something in my electronics bits box.

They are plated brass standoffs for mounting circuit boards.

Coincidentally they are almost exactly the same diameter as Lachenal and Wheatstone bolt heads, with a nice clearance hole and 6mm long. They are a fraction bigger which means they are a tight push fit into the hole the bolt head made.

So all you do is clean the hole out with a 4.5mm drill bit to a depth of 6mm, start the spacer into the hole, then pull it right in with the bolt. Fill around it and polish.

Before.

And after.

In the UK they are available from RS Components (the part number is 606-759) and are about 10p each. There are probably shorter ones too.

Hope it helps.

Andy.

-

Greetings from a newbie. I am looking to find an animal-free substitute for goat skin. I need it for the bellows gusset of a free-reed instrument. Has anyone had any experience with using synthetic materials for this purpose? Kind regards from the UK.

Hmmm. perhaps I just invented the cheap Chinese Concertina! Not much leather in them.

-

Greetings from a newbie. I am looking to find an animal-free substitute for goat skin. I need it for the bellows gusset of a free-reed instrument. Has anyone had any experience with using synthetic materials for this purpose? Kind regards from the UK.

Interesting point. I've been toying with the idea of constructing a "Vegan Concertina". I'm guessing that a lot of folk musicians might be committed veggies!

Andy.

-

Not sure why you might need to involve the tail stock. If the bar stock is the size of the thumbscrew it won't go anywhere. Cut the stock down to the threading size, make the thread, start to part it off after the top of the thumbscrew, stop and knurl the edge, clean up the edges of the knurl, finish the part off. I have a mandrel with a centred threaded hole in it (I use 7 BA rather than 6 BA, though I am in the process of converting to unc 4-40) which I put in the chuck, screw the new thumbscrew into the hole and then clean up the presentation face. Make another one.

As Theo says, don't worry about the thread not going to the shoulder. Theo always gives good advice...

Chris

I will give that a try Chris. It sounds logical. The mandrel's an excellent idea. It prevents crushing the thread, although I guess it could be threaded as the last operation.

Andy

-

No need for the thread to go right up to the shoulder. There is the thickness if a leather strap below the screw head.

Good point Theo.

-

I was looking at pictures of the inside of a Crabb Concertina and was wondering what the purpose of the hole in the center of the reed pan was. The hole is only in the reed pan and not in the action board so no air gets through. Is it just a chamber to let the sound reverberate? I noticed in Bob Tedrow's photo journal about making a zephyr here that he doesn't include one but Wim Wakker has the reed pan center hole also here

I'm not a concertina builder but I'm interested in the construction of them and was just curious as to what that hole in the middle of the reed pan was for.

Thanks

Hi Sean.

In the case of the Lachenals and Wheatstones, the hole was used in the manufacturing process for the routing of the reed slots. Look at this fantastic footagethat Henrik Muller sent to me.

I did an experiment. I stuck a piece of paper over the hole and drew lines along the edges of all the reed frames. Guess what? They all ended up at the centre of the hole (obviously!) The reason the hole is offset towards the small reeds is that the angle of the slots then stays the same. If it was in the centre, the long reeds would have a much steeper angle than the short ones.

Andy

Brass or Nickel silver for reed making

in Instrument Construction & Repair

Posted

Theo, it might be worth having a chat to Richard Mason at John Keatley Metals 0121 236 4300. Evidently they do lots of small bits'n bobs. www.johnkeatleymetals.com

They're oopnorth too.

Andrew