-

Posts

1,678 -

Joined

-

Last visited

Everything posted by SteveS

-

I have a metal-ended Aeolo 60 key baritone that I'm servicing right now. Should be available in 2 weeks or so. Might it be of interest?

-

It's leather externally (about 2mm thick leather), with wooden internal box. My thought is to see how it goes with 2mm leather (might be a challenge for a beginner) for my test piece. If all goes well, when I come to make the first case, my thought is to reinforce the case internally using thin birch ply.

-

I've attached a pic of the case I might copy - this is for a baritone, but I have a treble that could use a case, so I'll just scale down accordingly. I've been collecting leather working tools for some time, and have just recently bought a sewing kit with various needles, awls, and various coloured threads. I have edgers, skiving knives (and the facilities to sharpen them), and various punches used in leather sewing.

-

I've been thinking about making a leather case - copying an existing Wheatstone or Lachenal leather case as my starting point. I've sourced leather for concertina parts and bellows - and got a few offcuts of leather sufficient for a small test box, using box sewing techniques. Has anyone tried sewing a leather box? Looking at the technique videos on YouTube it seems fairly straightforward (hence the need for a test box). But I'm sure there are some things not explained in the videos that I'll run up against. I'd appreciate any tips / advice.

-

I'd read that gum sandarac will make the shellac a little harder - add too much and it becomes brittle. Right now I'm not using any additive in my polish - the combination of shellac (and natural wax) and 99.9 degree ethyl alcohol seems to be producing a good finish.

-

.thumb.jpg.e5ef9a111c1064c0bbea848f22aab7fe.jpg)

Tiny screws for Dickinson Wheatstone anglo

SteveS replied to Sarah Cardin's topic in Instrument Construction & Repair

Try using cocktail sticks - they tend to be made from a harder wood than that used for matchsticks. -

Does anyone use gum sandarac in their shellac finish? Some say to add a small quantity to the shellac, others say to do the final polish coat with dissolved gum sandarac. Instead of using gum sandarac, how about using shellac that hasn't been dewaxed?

-

Lachenal New Model Treble English Concertina | eBay

-

This concertina is still available. €1900. Located in Piemonte, Italy.

-

.thumb.jpg.e5ef9a111c1064c0bbea848f22aab7fe.jpg)

Ethyl alcohol and French polishing

SteveS replied to SteveS's topic in Instrument Construction & Repair

Maybe Amazon Italia can ship to France? -

.thumb.jpg.e5ef9a111c1064c0bbea848f22aab7fe.jpg)

Ethyl alcohol and French polishing

SteveS replied to SteveS's topic in Instrument Construction & Repair

I've no plans to drink it - we've got plenty of very good wines in Italy -

.thumb.jpg.e5ef9a111c1064c0bbea848f22aab7fe.jpg)

Ethyl alcohol and French polishing

SteveS replied to SteveS's topic in Instrument Construction & Repair

I think that the water content, since it doesn't evaporate as readily as alcohol, remains in the shellac for some time after application, resulting in the shellac remaining soft and tacky. I guess this then necessitates the use of a lubricant at the polishing stage. And yes, I'll ensure my containers are tightly closed -

.thumb.jpg.e5ef9a111c1064c0bbea848f22aab7fe.jpg)

Ethyl alcohol and French polishing

SteveS replied to SteveS's topic in Instrument Construction & Repair

Hi Geoff I found the 90° variety in hardware shops here didn't dissolve the shellac too well - it's mostly used for cleaning, and maybe there are other additives. It's also coloured red. I bought my 99.9° ethyl alcohol at Amazon Italia, and it's specifically for French polishing. However, I think a 5-litre container of ethyl alcohol will last me an awfully long time -

For French polishing, I have previously used methylated spirit as my shellac solvent. Here in Italy, the nearest substitute doesn't contain enough alcohol to dissolve shellac. I had to look for an alternative. I found a supply of denatured ethyl alcohol (99.9 degrees) and its use in French polishing is far better than using meths. I found that the application of the shellac with the rubber is far smoother, the alcohol evaporates quicker, the tacky phase of the applied shellac is shorter, and the surface hardens quicker than with meths. I've even not had to resort to applying a lubricant during the polishing phase. Also being clear, with ethyl alcohol there's no risk of a purple colour being imparted to light shellac finishes. What has been your experience of using ethyl alcohol?

-

Thanks Chris If bellows are so far gone, I've taken them apart to get the dimensions of the components. The beauty of using templates for bellows parts, is that I can easily fabricate them in brass rather than wait weeks to order and have them shipped. I won't be ordering any clicker dies for bellows parts, since there are a great variety of different bellows shapes and sizes requiring any number of dies. And a quick calculation suggests at least 4 dies per bellows - more for stretched bellows. With regard to the die press, I've not yet made a decision about whether it is right for me. I did however receive some very thin punches in the post today - the largest is 6mm in diameter - these should be ideal for making lever arm beads. I'll try them out later today.

-

Using a press with the clicker dies, set me thinking about what else it could be used for. For example, having clicker dies made up for bellows making - the alternative of course is to make templates for the parts.

-

I've found someone on Etsy who can make clicker dies for valves, and an oval die for a pad. Circular clicker dies are available off-the-shelf. I'll need a clicker press too, and a modest small press costs less than €200.

-

I'm sick of the additional charges for import to EU - we recently received a gift for my son, declared value £20 - we paid €12.37 in import duties and VAT. Looking to import commercial goods from UK into Italy should attract 0% UK VAT, but according to the Italian customs site, 22% Italian VAT (which is the norm) and 5% customs fees. Not too onerous, but still on principle I'd like to avoid dealing with Brexit Britain.

-

Thanks - that's a great idea

-

I looking to source some screws for attaching the wooden button hole board to the metal end (Wheatstone). I'm after 6 of these. Does anyone have a scrap concertina handy for donating some screws? Willing to pay for them, and postage to Italy.

-

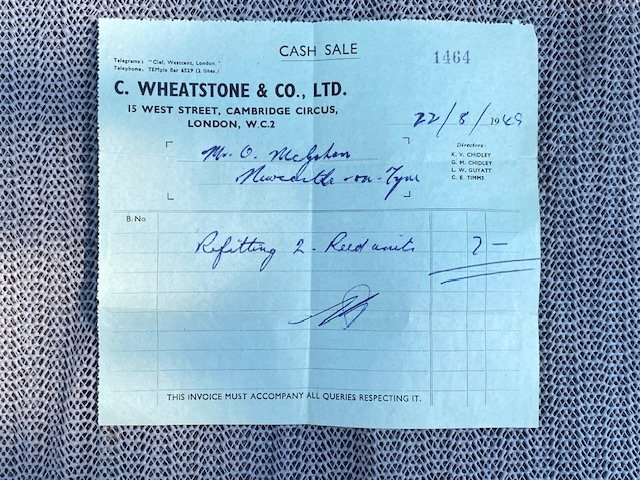

A Lachenal New Model 48-key Treble English concertina, with steel reeds. Reconditioned with new pads, new valves, and tuned to concert pitch (A=440Hz). This is a good example of a metal-ended New Model treble, plays well with a bright tone. The metal plating shows some sign of patina and finger wear acquired during the years, but this does not affect the playability of the instrument. One great feature is the provenance - having belonged to Owen McGohan, born in 1877 - and presumably, he acquired it new as a young man - around 1895 or so. This concertina would make an ideal upgrade from a tutor model - and will hold its own in a session. Includes the original case. €1950 Located in Alessandria province, Piemonte, Italy.

-

Thanks - I have wad punches for the pads in a variety of different sizes. My guess is for valves I'll have to have custom shapes made.

-

Given the difficulties in obtaining spare parts from the UK - essentially due to Brexit - I'm thinking to reconsider tooling up to make my own parts. I've got a lot of tools already, but what I'm missing are valve punches. Any recommendations for someone who can make me a set of punches for valves? Thanks

-

Thanks all for the replies. Another alternative is sandylaneman in Co.Kerry, Ireland. Does anyone have any contact details for him? He advertises on eBay, but I'd rather not use that site for comms.

-

Thanks Theo