-

Posts

80 -

Joined

-

Last visited

Everything posted by David Lay

-

I have designed theaters and auditoriums (auditoria?). The acoustitians always had us apply dense but soft material to walls from which undesirable reflections could bounce. The soft material (usually fiberglass board) cut reflections both at the surface and by attenuating any pass-through reflections that made it to the back-up wall. Lower frequencies always caused problems for adjacent spaces rather than for an audience. A heavy separating wall (mass) was the only way to mitigate that. Soft materials will definitely change the sound of a concertina wherever they are placed inside. Wood choices will also change the sound with their different densities. That mahogany might have resulted in a different sound in-part because mahogany typically has open pores. The pores possibly provide small chambers into which higher frequency waves enter and die rather than reflect. I suspect that the effect is subtle, however. (Based upon this principle, concrete masonry blocks are available with openings and internal chambers to be used for sound attenuation.)

-

Action Board Crack

David Lay replied to Stephen DOUGLASS's topic in Instrument Construction & Repair

Stephen. Saw your prior post about humidifiers, so can see that you are dealing with it. However, beware room humidification at 50% when it's very cold. Moisture can damage your home at that level if it migrates into walls and condenses there or on cold surfaces. That is the reason I prefer the case humidifiers. As an architect, I have seen condensation damage too often. -

Action Board Crack

David Lay replied to Stephen DOUGLASS's topic in Instrument Construction & Repair

Monitor them, of course, but also monitor the humidity of your instrument's case. If you live in an area where it gets very cold, moisture levels in the air can get very low. Try to hold near 50% relative humidity at room temperatures. There are guitar case humidity control packs available for this. Wood objects are particularly vulnerable if they are moved from a place with a temperate climate to a place with a cold or arid climate. All wood moves as it absorbs or gives up moisture. If the movement is restrained, it will likely lead to cracking. Plywood is more dimensionally stable and less affected. Also, wood moves more in the direction perpendicular to the grain than in the longitudinal direction. -

There's this post that might be of help:

-

Thank you. I calculated 50g/200ml = 2.08 lb./gal(US).

-

Interesting. I interpret that the name methylated is derived from spiking ethanol with methanol to make it dangerous to drink. Seems a bit mean when they could use something that makes you sick rather than blind. As I mentioned, other denaturing agents include propanol, and I just learned, methyl-isobutyl-ketone (MIBK). I can buy "off-road"/heating kerosene that is dyed to make it clear that the road tax was not paid in the price. (I am sure there are cheaters who put it in their diesel trucks.). I bought 190 proof denatured ethanol labeled as hand sanitizer - no dye.

-

Thanks to all for your great input! SteveS: When you say "1/16 cut", I interpret you are diluting your shellac with 16x more ethanol. What is you starting concentration? ...or have I missed your meaning entirely? DDF: What is "meths/alcohol"? I might guess you are using methanol. My web search result showed articles about methamphetamine 😐.

-

I have searched, but cannot find where others have made recommendations for applying shellac by the "French Polish" process, though I remember reading some. I tried the typical instructions found on-line and by an author, Tage Frid, using a 2# cut, a pad, and sometimes a bit of oil, but my result was bad. More recently, I went with what another author, James Krenov, advised using what is a 1# cut or even more dilute, and no oil. (Lots of coats, but then one web source recommended 30 coats with the 2# cut). I like the result. Frid wrote that for traditional FP, filled pores is usual. I left my mahogany with open pores and it is not glossy like I would expect from traditional FP. I used orange flakes in "190 proof denatured ethanol". (Ethanol will distill to 95% ethanol/water easily. Getting that last 5% out is difficult, and once a container of it is open it will absorb water from the air and be 95% quite quickly, making it 190 proof.) The labeled ingredients of my alcohol are ethanol and water, so I have no idea what makes it "denatured". Zinsser shellac from my hardware store gives a wide range for how much shellac is in their product, so it might be 2# or 4#. It lists up to 10% propanol as an ingredient, but nothing more scary. Propanol (rubbing alcohol) is a common denaturing agent. Shellac is said to go bad if not fresh but Zinsser does not have an expiration date on the can (??). Krenov thought the canned product an OK option provided it is diluted and strained. To be safe, I used flakes and as pure an ethanol product I could buy, freshly mixed. So, if I filled the pores and went to 30 coats or so of my 1# cut, would I get a glossy french polish? Also, the use of oil seems counter-intuitive. It seems it would polute the finish since alcohol and oil are miscible. What can be said about this part of the process?

-

Should be OK for a good length of time. It's not like polystyrene or polyisocyanurate plastic foams. It's also relatively inert with no leaching solvents or evaporating plasticizers.

-

Leaky 20-Button Concertina

David Lay replied to bummysteakpotato's topic in Instrument Construction & Repair

What make/age of concertina? -

Building a concertina with one kind of wood

David Lay replied to Vitto77's topic in Instrument Construction & Repair

If I only had 5mm panels, I would expect to laminate pieces together to get the thickness needed for some components. Walnut is quite dense, which will affect how you attach lever posts and otherwise detail the project. I wonder, though, how using only a dense hardwood will affect the sound. -

Has anyone got an active link to share for Sandylaneman?

-

This is what I used but at 1/8" (3mm) nominal thickness. The 1/8" material appears to be unavailable from this seller. I had another's product run out and switched makers to find that the definition of what you get as neoprene varies. I have had best success with the kind that is more firm than "squishy". ("Foam" vs. "sponge" in the Amazon descriptions, perhaps??) https://www.amazon.com/gp/aw/d/B07WVQF1DF?psc=1&ref=ppx_pop_mob_b_asin_title I put the sticky side of the neoprene to the velvet because it can be tricky controlling the amount of spray adhesive applied. If you use too much, it soaks through ruining the facing. The peel-and-stick surface is better for this, so I use spray adhesive to bond the wrapped edges. Note that in my experience, rubber adhesives eventually weaken; however, my oldest case is 4 years old and still good.

-

I have used velvet fabric laminated to 1/8" neoprene peel-and-stick sheets. The velvet is all synthetic - probably polyester. I have been using spray-glue to hold folded-over edges and then hot glue to hold the pieces in place. Corner blocks are wood with neoprene on the sides that contact the instrument. I like Alex's suede choice - should last forever!

-

Shoe polish for the discoloration! (I use a soft polyester buffing towel on my knee. I simply thought it would be a good idea. They are sold in automobile part stores/ departments.)

-

Morse has stopped making instruments just this year. AC Norman: http://www.acnorman.co.uk/

-

Can Tuning the reeds up one note?

David Lay replied to genepinefield's topic in Instrument Construction & Repair

Here is Bob Tedrow's short lesson. https://www.facebook.com/Robert.Earl.Tedrow/videos/592850942546296/?idorvanity=2240273277 -

How long does it take to make a Concertina?

David Lay replied to Notemaker's topic in Instrument Construction & Repair

Different makers take different approaches, of course. The Button Box let me know that they had others make their end grilles. Other components like bellows might also be contracted to others. Reeds are more often purchased from a factory to keep the amount of hand-work down. If a maker works at it, making or having others make each component in batches, then the time required is really one of component assembly. (Just like Eli Whitney's muskets!) You can generally tell by the price, the wait time, and by how much customization is offered which makers do all the work in-house. -

I sought a lower tuned instrument a few years back. Used would be a great find; maybe you will still find one. New seemed more likely to be successful to me. I found only two makers with endurable wait lists. Morse has recently stopped production on their minus-1 octave C/G "baritone", however. (It is confusing to me what defines a tenor, baritone or bass instrument. Maybe a tenor is a G/D?) The other maker was A.C. Norman. He makes a minus 1 octave C/G "baritone" and a minus-1 octave G/D "bass". (Minus 1-1/2 octaves from a typical C/G.)

-

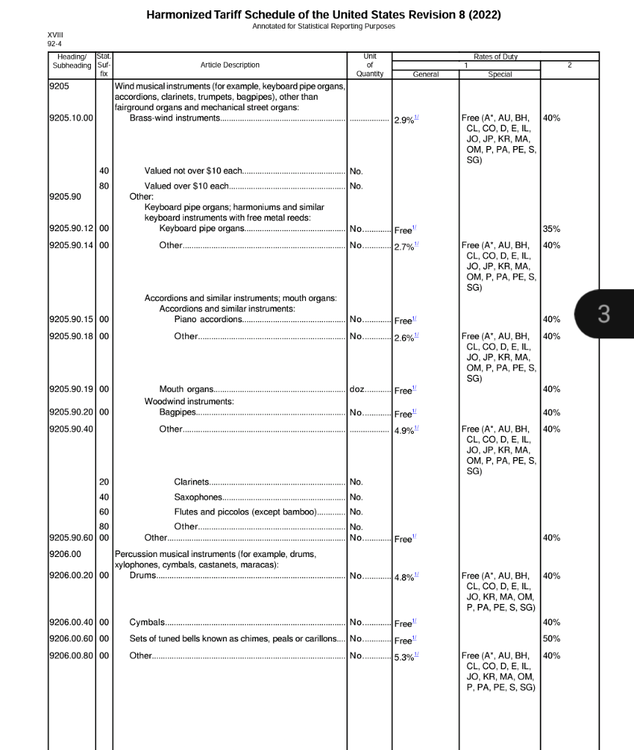

UPS does not put any effort into identifying the instrument classification and the duty. They will get it wrong without a care. Do your own research in advance and have the forms and your tax number submitted with the package. (Better to use another shipper.) Search for the "Harmonized Tariff Schedule of the United States". A piano accordion is free and just below that is listed "other" with a rate of 2.6%, however some trading partners are designated "free". The heading for "other" is 9205.90.18. The piano accordion is 9205.90.15. We have a free trade agreement with Canada for Canadian goods and UPS asked for a 5.3% duty from me without ever asking if it met any criterion for less.

-

I have experienced the same on two modern (and therefore relatively new) concertinas and have been struggling to understand the reason/ find a solution. I have considered the ideas discussed here including air leaks, misbehaving valves, reed tongue position at rest, various reed chamber resonance theories, and reed design. So far, I very much like Alex Holden's note offering that designing a balanced reed is a refined skill (and so perhaps not a skill every maker has). Still, I must not conclude this to be the case with one instrument since the reeds were not hand-made (possibly Harmonikas). Any restoration/repair expert, please suggest what 3 things you would look for if an instrument came to you with slow-to-respond and muted right-hand reeds - for the sake of the question - all those above B5?