RogerT

-

Posts

79 -

Joined

-

Last visited

Posts posted by RogerT

-

-

Actually, I think it is very helpful..obviously only occasionally, when air leaks are a particular problem. You also need a stethoscope.

-

-

On 1/4/2024 at 7:32 AM, Fanie said:

Now, it is easy to tune a C-reed to C/D

I'd probably use a C# reed and flatten/sharpen, or a D reed and flatten to C.

-

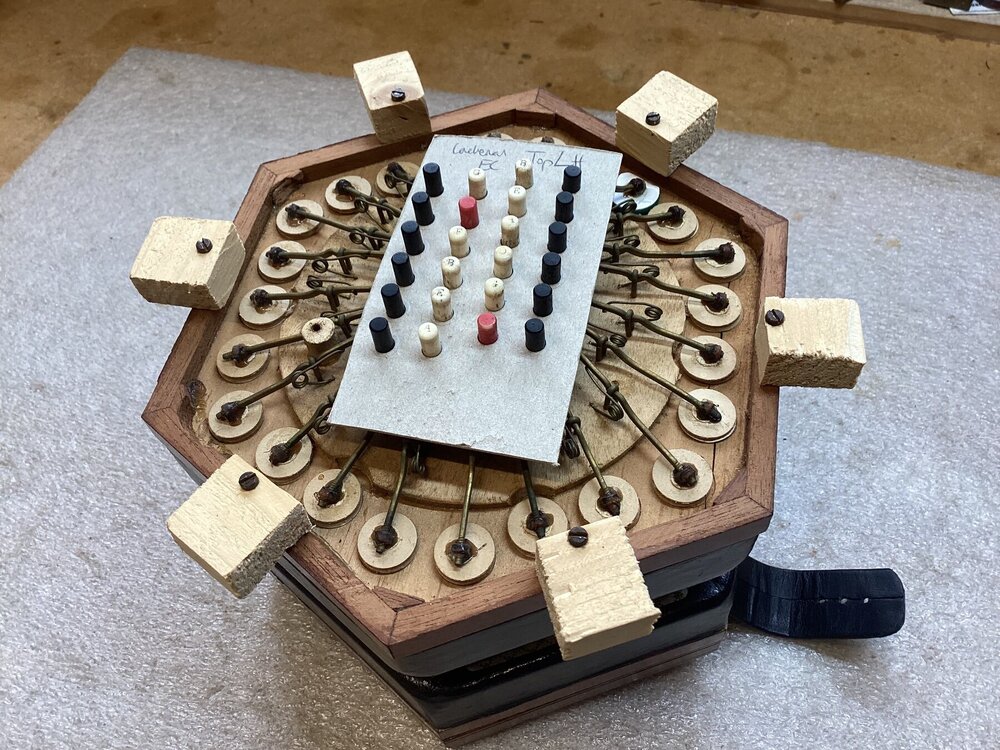

Hi, i've got a Lachenal EC, steel reeds, tutor model, serial #38559. My guesstimate is 1905 but maybe not. If you'd be kind enough to check the date for me, that'd be great.

thanks

-

I've got a load of tiny…i mean really tiny (like 2 or 3 mm diameter) magnets. They would be ideal to try out your idea. You can get them for very little on eBay. You may find that fine tuning is the issue…if they stay put with the reed oscillating. If i get some time i might experiment myself…I'm now curious to see if this works.

-

Ah right. A temporary solution.

-

Oh b*gger. That's where i got my leather skins. Damn. However, Russells in Suffolk supply bellows leather to organ makers so perhaps that is another source.

Good job i bought my lovely handmade gloves from Pittards last year.

-

Curious as to why you don't want to use solder? It's an easy effective solution and is reversible.

-

I use modern PVA wood glue, which sets pretty hard. Any glue that doesn’t set hard is a problem because you don't want the pad to move on the end of the arm. Removing and re-gluing pads may or may not be made more difficult by this choice of glue, but for the repair in hand it works well and in any case I make my own pads so replacing them isn't an issue. So I guess it's a repairer's choice. I've tried quite a few different glues and this works for me.

-

This guy seems to be under-followed. This is a great (free) instructional Anglo video. Marvellous stuff, if you want a compacted walk through of ornamentation. So many vids are aimed at the complete beginner, whereas this is definitely in the intermediate phase.

-

1

1

-

-

I would check the valves. I keep encountering the following problem: someone has cleaned and revalved a concertina (and an unsuspecting buyer has got hold of it in a 'restored' condition) but fixed valves that are too thick and or has glued too much of them so the valve is restricted…but they obviously never checked the result of their work. And the smallest tweak can alter the behaviour of the reed, taking it from dull to bright. Sometimes just flexing the valve up and down/back and forth can fix the issue. Or I replace the valve, taking care just to glue the very end of it and not half of it. Leather accordion valves work ok..the funny shape is just so they fit in the tapered chamber. If you have a way to get the reed pan out and lay it flat on some tuning bellows, block the chamber end and you can then observe the reed working and play around with the valve. The other problem is that the cleaned reed (all lovely and shiny) hasn't been 'voiced'…in other words the gap has been set correctly, or of the reed has been distorted by cleaning, the shape and set haven't been optimised. Or the reed is loose in it's slot. All of these things can be dealt with on the tuning bellows. If it sounds good on the tuning bellows but dull in the instrument, then it's an air issue…the pan isn't sitting flat against the action box or some other problem.

-

To soften them up I sometimes pull them off, soften by manipulating them (rolling up in both directions, gently scraping with a metal blade etc) an d then glue back on. It's quite difficult to get at the valves inside the chamber and only takes a moment to pull off and refit. Or I pull off and glue on a new one. However, this can alter the tuning and alter the reed behaviour if the valve doesn’t open properly or lets in less air etc…so beware. Normally I fit valves before any tuning for this reason.

-

1

1

-

-

46 minutes ago, Peter Laban said:

The fact these last few posts attempt to lay the blame at the EU's door

It’s a bit of a stretch to read that from my posts (if that’s what you were saying). And anyway I'm a big fan of the EU. I’m merely pointing out that there seems to be more friction getting stuff from the UK to the EU than the other way around. You can speculate on the reasons for that. I don’t think it applies to trade between the UK and EIRE AFAICT.

-

3 hours ago, Peter Laban said:

That statement is just plain silly.

I could qualify it and say that the EU have less incentive to make smooth and easy importation work well by small companies and individuals from non EU countries (because most of their trade is driven by geopolitical boundaries …the EU…which incidentally I think is a brilliant thing). And anecdotally this seems to be the case. But it may also be silly. Thanks for pointing it out.

-

Anecdotally, it seems Brit import processes generally work ok these days, because that’s one of the things that had to be sorted post Brexit. But working the other way around, where the receiving country is in the EU, it often either doesn’t work at all or is slow and expensive. I assume this is because *all* imports to the UK have to be processed through customs, whereas EU countries have no interest in having working and efficient processes from non EU countries.

-

Alex, did you find the original jig, with forms for the folds, an unnecessary complication? I’ve looked at you Insta posts (now following). Having the frames fixed to the jig must be crucial? To get the spacing properly set?

-

Mostly you can't, because the reed pan sits in a particular place in the end of the bellows (it's normally marked so you always put the reed pan back into the bellows frame in the correct orientation), so the only thing you can rotate is the ends, but if you do that the buttons/air holes etc won't line up with the reed pan.

-

Ah..yes..I remember your post now. I will have another look at it. Thanks

-

I know it’s an old question, but is there a suitable card material (and advisory thickness) available in the UK for making bellows?

I think some makers create their own composites..but are there any 'over the counter' cards that would do the job?

in one thread on c.net Presspahn card is suggested..it’s obtainable in the UK in varying thicknesses. I think it needs to be at least 1mm thick..?

And on construction itself..the faces are all hinged with glued tape (and leather binding). I assume this is because folds would be too stiff?

Accordion bellows are made from strips of folded card, plus corner gussets (and metal corners etc). Probably the cheaper (for instance Stagi) concertina bellows are made this way?..I don’t have one to hand to check to see if they are or not.Finally, some makers use an armature/jig to form the bellows, with forms for the folds, whereas some do not..they just used a hexagonal armature to suspend the bellows (I have one like this).

in this video of APJames making a concertina he uses a complicated looking jig. But how does he remove it once the bellows are formed? I assume he unscrews the metal plates and removes the central ply forms…does anyone know? You see the jig from around 2 mins (if lower the vid speed you can see it in reasonable detail).

-

1

1

-

-

I completely agree with d.Elliot…esp the list of things that can affect the 'go' of an instrument. Improving the compression in particular can make a big difference, and old Lachenals can be a bit leaky, though you might not realise it. It’s worth analysing the failings of your Lachenal to see if some less radical work will improve it. But really, I’d not be spending money on changing the action. Find an instrument that does what you want and buy that.

-

As it’s new it’s still under warranty so really it ought to go back to McNeela. The gap looks ok (on the outside e.g. push reeds), so if it’s breathy in both directions, but just on those two notes, it might be a leak between the two reeds. The wax mIght look ok but might be leaking air between the two chambers. In practice and if I was investigating it I'd pop off those reeds, inspect inside for anything obvious, then reseat them. This can be done with a soldering iron and some care. This may or may not fix the issue, but if the reeds and valves look ok it’s where I would start.

-

1

1

-

-

It might be the sound of valves closing.

-

A photo of the inside would help. You don’t say if you bought it new. If it’s got accordion reeds these instruments can be tricky to get back together without introducing air leaks. So if/when you take it apart to take a photo be super careful when you reassemble it.

-

Dave…who did you get to make them?

Troubleshooting leaky action box

in Instrument Construction & Repair

Posted

I wasn't really asking for a diagnosis of the issues…yes there is a crack…i was just showing how it's possible to put the action box on so you see it working and diagnose all the issues, not necessarily a technique to everyone’s liking but all the same v useful on occasion. Yes I know about using a bright light etc and I don't always do it this way….I repair concertinas professionally so I've got a good grasp of how to go about it. It's really no extra effort to do this.