-

Posts

41 -

Joined

-

Last visited

Posts posted by Bruce Thomson

-

-

Notice in this video (about thumb strap ideas) I created an under-knees strap that holds my concertina very securely for playing see video below.

It also gives extra pull out of the bellows, meaning less interruption of playing.

It's so good that without that strap the concertina feels very floppy and awkward and obstructed.

I've played almost every day since January 2010. I'll never go back to playing without the under thigh strap.

The thumb strap idea isn't vital, it was an experiment. I didn't bother adding it to my Lachenal concertina, but might one day.

-

Yes thanks - I'll try to contact him and invite him/anyone interested, to our Facebook group, Concertina Technology, regarding the (MIDI also) Concertina Nova project.

English-type concertina for a start, but other types later if things go as hoped.

That group is at https://www.facebook.com/groups/1771580879534725/?ref=group_browse_new

We're hoping to have a prototype within a few months (2Q 2019) if the builder has spare time to do the work. He's busy with s house move and his job at the moment.

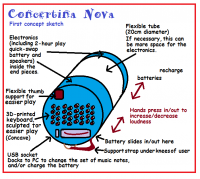

The design specification aims to produce a totally self-contained (wireless, with battery and speakers contained in it) but with USB socket for loading with any desired .WAV sounds)

It's not a commercial product, just a collaboration between me (Bruce Thomson, concept and specifications) and the technologist (Nguyenvy Ngo in Vietnam)

Hoping the price of it will be about $US450.

-

Hi Steven,

- I have an old Lachenal too. When a note either fails or plays constantly, I simply give it a several bashes with the heel of my fist - which dislodges particles of dust from the reed, which makes it work fine again. I have opened it up a few times, but that's tedious.

- When I shock it (cushioned by the heel of my fist), I hold it at different angles, and press the button OR leave it closed, giving variety of conditions for the particle to be released from.

- This method may horrify a few members, but I've done it successfully for years- Early next year I hope to totally replace my concertina with an electronic one, the Concertina Nova, that doesn't have all these physical complexities and problems. My colleague in Vietnam, Nguyen Vo, is building for me in Ho Chi Minh City. It will have a good quality concertina voice, plus any other suite of notes the user wants to upload as .WAV files. Still has bellows, but eventually I want to eliminate the need to back-and-forward interrupt the playing and unbalance the concertina.

- You/anyone can follow that project on Facebook at the 87-member Concertina Technology group I operate. http://bit.ly/2P0y24x

-

1

1

-

-

-

I'm currently attempting to outsource the creation of the Concertina Nova, using UpWork.

There are several bidders competing to do the job, I'm unsure whether any will do well, but progress is full of trial and error.

See sketch attached, and website with more details at http://bit.ly/1TFLQ2z

By the way, the flexible thumb strap, and the under-knees strap are well proven after a year of trial, on two concertinas I have.

I wouldn't go back to a conventional concertina now.

If this Forum isn't suitable I'll move the discussion to the Concertina building and repair forum instead.

Kind regards,

Bruce Thomson in New Zealand.

-

Hi folks,STATUSHere's here's a summary of the current focus of the 'Concertina Nova', and some replies to your helpful comments.- I'm delighted by the increasing possibility of creating it, thanks to your and other enquiries in hand.- Delighted now to be conferring withJim MacArthur (building a MIDI concertina printed circuit board)Paul Hardy, Don Taylor, Chris Ball (each building a MIDI concertina currently),Roy Whitely (very experienced converting to MIDI concertina) currently- This is a 'from scratch' refreshing, fun, rethink of the concertina, rather than a conversion of existing concertinas.- Help me leap us into the 21st century using 'now' technologies, materials- Let's equal/surpass today's existing top concertinas in sound quality, and (most important), ability to express ourselves more richly and satisfyingly in music.- Especially let's use MIDI electronics to transcend reeds and probably bellows (use mechanical force to give 'feel' and 'effect'), but for now prob retain at least 'dummy' button/lever structure to retain the 'feel'. (Jim, Roy)- The 'real concertina' sound is highest priority, but it's got to have unlimited other voice customizing at low extra cost for those who want it.- Remember horse and cart? That's where existing concertinas are. Now think of the Tesla Model 3 (see https://www.youtube.com/watch?v=ExXGy_oIY30 )- Let's design it to be a tenth of the price of the world's best concertinas, making it widely available and popular for millions of school kids, family/friends campfire gatherings, parties, etc.- Completely self-contained with battery enough for 10 hrs of playing, and speakers.- As 'democratic' as possible: Open source parts & software, designed to be simple for anyone to fix. Cheap as a guitar. More rugged than a guitar.

- BUT if desirable, I know how to patent any excellent final design to protect it from capture by a competing, obstructive vendor.- Several of us might be building their own, but conferring with each other, ending up with at least one that thrills us, and thousands of people in future.EASIER, FASTER COMMUNICATIONSAlthough I love old Concertina Net, this is 2016 and I'm used to Skype, YouTube and FaceBook.I encourage any and all of you all to connect with me via Skype video session - My ID is Bruce Thomson in New Zealand.Also welcome to use Skype telephone calling, or ordinary phone to telephone me. NZ is 64 06 357 7773 or (cell phone) 64 021 176 9711My hope is that in this adventurous project we'll get to know each other as humans and have a lot of fun as it advances.If you email me your phone number, I can try to phone you at my expense (very cheap if I Skype telephone you).RIGHT NOW ACTIONI'd love to talk with Jim, Paul, Roy, or even all together in a Skype session at a globally okay time.Things like the best way to achieve button feel and effect, doing a run of Jim's printed circuit boards, costs involved.I AM willing to PAY if I have to. E.g. put hundreds of dollars to get the parts I will need to produce the Concertina Nova IF it leads to something the world will love.

I AM happy to hear your pitch if you ask me (e.g. Chris Ball) to pay you to create a useable starter playable prototype (to pretty up later) towards that.My knowledge of electronics exists, but is limited.Remember I'm only doing all this to get myself a superb MIDI concertina for expressing myself even better than my present joy of playing.If you haven't yet, DO have a drool over today's best manufacturing tools, at... https://www.youtube.com/watch?v=o6g9eTP5H1QKeep talking here. It'll help me get there. =)Regards,Bruce -

Thanks, Paul, Jimmy, Greg, Don, for the very useful ideas and suggestions.

Yes, I have my old Stagi tenor to convert, or even my Lachenal treble.

If at all possible I'd also like to put the synthesizer and battery inside the thing, to make it portable for kids, anyone.

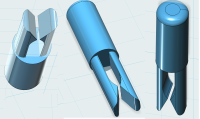

Paul, re. the a good button/switch array I'm hoping to use 3D printing of as much as possible of the whole concertina. I've taught myself to use Sketchup (see example of button design I did).

Imagine if we trial-and-error ended up with a design that

- sounded really excellent

- anyone could cheaply either get printed by an online 3D printing shop, or at their local library's 3D printer (our library as several) and order off-the-shelf electronics to screw into the ready made holes. =)

- could fairly easily be experimentally modified/evolved by anyone in Sketchup and created overnight to try in the morning.

- was so cheap, a teacher or folk club could print ten and teach a classfull of learners!For the sample sounds, I was wondering if I could simply record sounds from my Lachenal treble, enhance them with a mixer, save as MIDI files somehow, and use that. Anyone know?

And I totally agree about the joy of playing other instruments using the concertina interface. But I most of all want a good quality concertina sound, and if possible, make it all cheaply available to everyone in the world who'd like it.

I'm trying to contact Roy Whiteley, but the phone number on his website fails when I call, and I haven't had a response to an email I sent.

Are any of you able to contact him? The phone number on his website is (44) 07519064196.

It thrills me to see already made MIDI concertinas, and to know the electronics are not expensive.

I'm sobered by the task - not sure I could do it. 'Might see what it would cost to get Roy to do it if he can.

Freight to/from New Zealand, plus customs on entry here can be expensive, 'dunno if I'd have to pay hundreds of dollars GST.

'Grateful for any help contacing Roy Whiteley.

Thanks again,Bruce

-

I'd still like to have/make an 'everyone's' budget electronic concertina...

What's the easiest available way?

I'm a player rather than a builder, I just want to be able to create a custom one that will help me play the ways I enjoy most.

If there's a simple kit of the electronics to save me time, I might see if I can create a MIDI concertina with a sculpted keyboard that better suits the arc of the fingers. I've heard of pressure-sensitive buttons, so I'd like that kind, and any other such features to give ability to play expressively.

If possible I'll make it battery-powered too, for portability.

Any helpful advice/participation will be welcomed.

Thanks,

Bruce Thomson

palmytomo@gmail.com

-

Hi John - Thanks for posting this - I need a tuning rig myself, for an imminent major renovation of reeds of my battered Stagi tenor-treble.

It would be good if you used a smart phone to take a few seconds of movie of the jig so we could see it working. If you do, post the link in this conversation.

I'm pondering about what I should build, preferably compact, and continuous-stream rather than a puff type.

I just found an interesting video on YouTube of a pro tuning reeds, showing all his equipment.

See https://www.youtube.com/watch?v=GgYYyn72HLI

I notice he's hammering without using ear protection, which will deafen him eventually.

Also very interesting that he's using a belt sander for super-fast adjustments of pitch.

To speed up the video you can click the right-click the cog at the bottom, and choose 2X speed or 1.5X speed, etc.

Thanks again,

Tomo

-

PLEASE, PLEASE folks, we've GOT GOT GOT to get the price of good concertinas down.

That appalling 'admired' price excludes even excellent players, let alone the public.

I'm deeply frustrated not to be able to own an instrument like that.

My existing old Stagi tenor-treble is worn out from daily playing and play-outs in public.

Let's keep thinking of ways of creating beautiful-sounding, nice looking concertinas that almost anyone can afford - under $1000.

'Probably by 3D-printing all or some of the parts for exact precision.

To me, the value of a concertina is not it's 'heritage' or 'tradition', or 'its awesomely painstaking precision and construction',or even its appearance.

It's the emotional human communion it enables, either just me to myself, or with others, from the human-emotion sounds it makes.

And I'd like thousands of people, especially young people, to have that, not just the few that do now.

Around campfires, with family voices together, accompanied by guitars, in backpacks at Youth Hostels, in the quiet times late at night after a party among friends.

-

In case anyone's interested, in addition to...

- the under-thigh strap I'm now using to stabilize the concertina and to give me about 30% more air

- the swivel thumb strap I'm using to give hand flexibility in all directions

...I'm also now using a 'rail' mounted thumb strap (still swivels too) so I can slide to the higher range or back to get lower notes.

Video is at https://youtu.be/UIQoBGEBbjQ

Photo attached.

One thing I'd be glad to know is whether my junky old experiments Stagi tenor treble can have a bellows mod that will muffle it and give it a nice fruity tone like a Wheatstone.

Many months, someone gave me some good ideas about muffling, but I got distracted by a million things and have forgotten what they said.

-

Hi Tiree,

I do 'Mickey Mouse' fixes of my concetinas myself (I have two) to save money and time.

I do it handyman style, 'would horrify and disgust artisans who make beautiful instruments and repairs (and charge a lot for it)

But I play every day without fail, enjoy the music, tolerate imperfection, have fun with friends.

AND I've invented some VERY successful improvements that make it much easier to play, e.g.

- swivel thumb straps for my English,

- under-knee strap that enables me to pull the concertina out with my legs, gaining 30% more bellows capacity

- replacement buttons that don't break, for my junky but good old Stagi tenor see attached picture (I just pushed a stick of it through a stove-heated bolt hole to get a nice round rod to cut into buttons)

On YouTube you can see those at and https://www.youtube.com/watch?v=HDyjTI1K1M4

I'm resigned to the risk of ruining parts or the whole instrument, but I've many times done repairs free or low cost that would have cost a fortune.

In this forum there's lots of good pictures and advice and people far more capable than me, and you can get parts if you Google 'Concertina parts'

Send away for the Concertina Repair Manual, excellent, by David Eliot. I gained a lot from it, it's well written, pictures, clear, comprehensive.

You can Skype me if you see me online, my ID is palmytomo

Generally I think the concertina needs a major redesign, because it's about 200 years since it was created.

I wrote a requirements specification for that, the 'Concertina Nova'

If interested you can view at https://drive.google.com/file/d/0B-4satLcOAKGNnRjNE5SNW03UXc/viewNote, I haven't yet got any of it 3D printed, but one day that's what I hope to do.

Regards,

Tomo

20 Lyndhurst St. Chelwood Village,Palmerston North, New Zealand

06 357 7773

021 176 9711palmytomo@gmail.com

-

New kind of button.

Recently I've been creating replacement buttons made of HDPP plastic - it's 'greasy' plastic that lubricates itself during its movement, so there's no need for felt bushing. But maybe the felt bush also prevents vibration, and of course the red felt looks beautiful.

See photo.

-

Bob - What kind of leather baffles did you use, positioned where? How thick leather, what type?

I put tape over the outside of my Stagi tenor-treble 56 key, but it just made it sound bleaty and cheap.

So I use earplugs each (daily) practice, but I'd like it to be quieter and mellower rather than 'bright.

Do you think glueing soft leather on the insides of the end pieces would be worthwhile? If it would fit, and with holes for the buttons.

Currently I'm really enjoying replacing the Stagi buttons with my own, extruded HDPP plastic forced through an ordinary 5mm hole in a bolt held over the stove gas element.

Bruce Thomson in New Zealand.

-

Great to watch this, folks.

If it worked it could bring a revolution in concertina compactness, lightness, simplicity of construction, and cost if it worked.

Maybe set up a small box rig that its whether a reed would work that way

Especially note what happens when the push changes to pull on the same note

- I suspect the reed will be 'slow', not responding until the air current fully changes.

Bruce Thomson in New Zealand.

-

Hi Linrose,

I'm no expert, just a person who fixes my own Stagi Tenor-treble 56 key concertina quite often (it's 5 years old and gets a very rough life), and am trying to enhance it in various ways.

- Can you posts a few photos of the insides of the concertina to help us muse about possible rattles?

- Can you record the rattle so we can hear what it's like? (Maybe use the Windows Sound Recorder, or mobile phone, or do a video and post it into YouTube, explaining the situation.

Cheers,

Bruce Thomson in New Zealand.

palmytomo@gmail.com

-

Very interesting question.

My guess would be that to build the resonance that brings a sound, it would have interrupt the note too long.

The reed might be 'slow' to respond after a direction change.

'Anyone know the official reason?

-

Good on you, Ruediger - I'm keenly watching your progress and would be happy to confer by Skype or Google Hangouts Live if you were interested.

I especially like your 'revisionist' attitude to the concertina.

Basically concertinas haven't been greatly revised for about 200 years. Mostly the changes seem to be enhancing the existing design without 'rethinking it boldly'. Some hours of musing could provide the world with a cheaper, more robust, more adjustable, easier-to-open-and-repair, possibly even nicer-sounding instrument than any we've yet seen.

By chance, this week I replaced a button by sculpting some HDPP plastic to make a one-piece item (See attached photo) It seems better in concept than the plastic-with-metal-hook version that my Stagi 56 key tenor-treble has. I've done videos, but haven't edited and published them yet. Of course, 3D printing of them is the next step. I'm just busy with house renovation at the moment.

Bruce (Tomo) Thomson

20 Lyndhurst St. Chelwood Village,Palmerston North, New Zealand

06 357 7773 021 1 76 9711

palmytomo@gmail.com

Skype: palmytomo

Google+ Bruce Thomson

-

If it were me, I'd consider

- whether the pads actually cover the holes well (positioning)- whether there's grit on the underside of the pad, or where it sits- whether the pad could be replaced with some latex or other flexible material

- whether the springs weren't applying enough pressure (replace them or 'stroke' them to produce more tension.

- whether the button connection was somehow actually keeping the lever pressed down enough to allow air through, i.e. not truly relaxed, bent lever or something like that.I'd certainly be sure it could be fixed, and would persist until I fixed it.

-

Thanks, Don, for reporting your experiment - very interesting.

My concertina is much too loud too. Most of them are, in my opinion.

I've unsuccessfully tried blocking, with tape, most of the curly vent holes of my Stagi tenor-treble English concertina.

It did quieten it, but the tone became a horrible, cheap, plasticky bleaty sound.

I might again one day try with more sturdy padding over those holes instead of tape that tends to buzz

Since then I've just worn heavy duty industrial earplugs (32dB attenuation) when practicing.

If I ever end up creating the Concertina Nova I may in advance find out whether smaller reeds are appropriate.

Presumably the frequency of resonance of any note is still achieveable using reeds of different mass.

The engineering is so complex I'd confer with existing experts.

The perfect experimenting environment for the engineering would be a virtual world (such as SecondLife).

Create a simulation of physical spaces and reeds etc. Mathematically credible within limits.

Design it so that we could vary sizes and mechanical properties.

Thus explore all sorts of configuration of reeds and reed cavities etc, to hear the likely timbre.

Even better, use neural net artificial intelligence that autonomously learns what we like regarding timbre'

Then set it to trying billions of combinations of variables until it gave us marvellous new sounds, specifying the metrics of the configuration.

Ray Kurzweil did similar to that very successfully for keyboards in the 90s. See https://www.youtube.com/watch?v=HpfPyOD1Gks

Regards,

Bruce Thomson in New Zealand.

-

Really beautiful imagination and beautiful materials and quality of work.

If you have a YouTube vid of it played, it'd be interesting to hear it.Cheers,

Bruce Thomson in New Zealand.

-

The video of Anthony James at https://www.youtube.com/watch?v=E4QHWas4G2Iis excellent, thanks, Marty.

'Beautiful work, beautiful natural materials, lovely appearance. And excellent video clarity & content.

I notice the holes aren't sleeved with that red woven felt. I don't blame him for a moment - I'd never bother myself, the benefit probably being little or nothing.

I wonder though whether a compromise might be possible by making a sandwich of wood, felt, wood.

The felt hole would be slightly smaller than the wood hole making the button ride smoothly and sound-deadened on the felt, clear of the wood.

I'm still smouldering with the desire to create an ergonomic sculpted keyboard concertina, possibly by 3D printing as much as possible, but the project is just a hope.

I contracted a local engineering co. for $400 to CAD & print the end pieces of my Stagi tenor, but their printer couldn't do an object that big (20cm corner to corner). By then though, I was pleased to cancel it in favour of thinking more before proceeding. 'Maybe buy a machine, learn how to do the CAD needed, collaborate with people already skilled in various ways, maybe combine forces.

I've found 3D printers, even those costing, say, $3,000, are still slow - e.g. a hair comb takes half an hour. A sandal four hours.

But the beauty is that if by trial-and-error a really excellent, better new design is achieved, cloning it could be simple and cheap for the whole world.

The draft requirements spec for the Concertina Nova is in Google Drive at... http://tinyurl.com/kueadb4

There's a Google Group dedicated exclusively to it at https://plus.google....908489357489215

Anyway, cheers, and thanks again for posting.

Bruce Thomson in New Zealand.

-

REASON FOR ATTEMPTING 3D PRINTING OF A CONCERTINA

Concertinas are too expensive because of complexity and difficulty of manufacture and repair, etc.

So I've decided to start 3D printing parts to create a better kind of 'people's' concertina - it's the start of my Concertina Nova project.

It's explorative - 'may take years, but the aims are:

- use 3D printing to experimentally revise the form of the concertina for better ergonomics and easier playing, yet still good sound

- to 'democratize' the concertina by making it available as a cheap, robust instrument at 'guitar prices'

- make them so popular that they'll be seen round every campfire and at every party, in harmony with guitars and voices.

ACTIONTomorrow I'm paying a local engineering firm, Absolute TOoling Solutions, to copy- 3D-print the outer ends of my tenor-treble, with

- non-conical holes so the buttons won't wiggle

- pinholes for ventilation, to reduce the glaring loudness while still allowing air flow.That experiment will cost me $400. It gets me

- alternative end pieces for my concertina

- CAD drawings I need for future redos (probably using my own 3D printer later)SEE THE CURRENT DRAFT REQUIREMENTS SPECIFICATION OF THE CONCERTINA NOVASEE THE 3D PRINTERS AVAILABLE IN NEW ZEALANDI may be buying a 3D printer myself, perhaps the one shown at..http://diamondage.co.nz/product/moa-3d-printer/ because it can 3D print itself and I might create others to use or sell.Bruce (Tomo) Thomson20 Lyndhurst St. Chelwood Village,

Palmerston North, New Zealand06 357 7773 021 176 9711 palmytomo@gmail.com -

mthatcher

You're doing the right thing by asking, and considering fixing it yourself.

You can save a lot of money and time that way.

I would certainly try to get some beeswax and repair it myself.

Not sure how I'd melt the wax and quickly bed the reed before it melted.

Maybe have a heat gun blowing, to slow the setting of the beeswax.

I've used a soldering iron on mine to tidy beeswax once.

If that failed, I'd grimace for a moment, but ponder about why and try again.

All the while I'd be learning - useful for future economical repairs.

If that failed, I'd consider getting a repairer to do it.

Good luck!

3D printing button?

in Instrument Construction & Repair

Posted

Eric, I've replaced several buttons much more easily than 3D printing, by buying a special plastic called Polymorph that you can order online or get downtown, for about $15 a kg.

It melts at 60º C, meaning that you dip it in very hot water to make it mouldable and drillable with a hot wire or drill. Roll out a suitable-diameter rod of it, cut it, drill it, etc.